Metal Seated Ball Valve VS Soft Seat Ball Valve

Soft Seated Ball Valve

The seat ring (seat insert) in contact with the ball part is made of soft material, such as PTFE, RPTFE, Nylon, Devlon, Peek and so on.

The soft-seated ball valve is suitable for clean fluid without any particulates and relatively lower temperature. They’re great for applications where chemical compatibility is important and where the tightest seal is the key. It is less expensive than metal-seated ball valves.

Soft Seat VS Metal Seated Ball Valve

| Metal Seated Ball Valve | Soft Seated Ball Valve | |

| Application Fluid | Abrasive fluids with particulates,high viscosity heavy oil,slurries,etc. | Clean fluid without any particulates |

| Working Temperature | Especially for high temperature up to 650℃ | Temperature limited up to 250℃ |

| Seat Material | Cr3C2, Stellite, Tungsten Carbide, Ni55 | PTFE, PTFE, Nylon, Devlon, PEEK, Delrin |

| Available Size | 1/2”-36” | 1/2”-48” |

| Pressure Rating | Class 150-2500 | Class 150-2500 |

| Torque Value | Higher | Lower |

| Price | Higher | Lower |

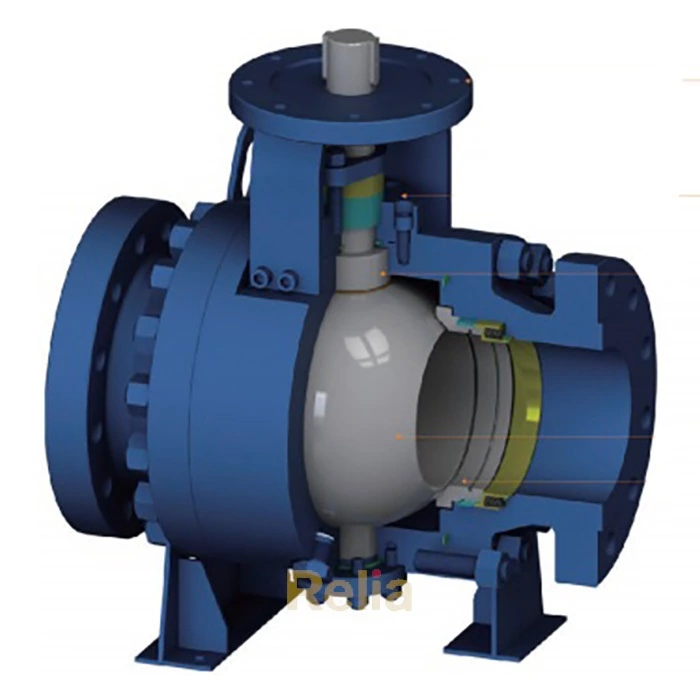

Metal Seated Ball Valve

In contrast with soft-seated ball valves, the seat rings of metal-seated ball valves are made of metal, such as Stellite, and TCC. Metal seated ball valves are more durable than soft seated ball valves because they can withstand harsh conditions such as abrasive fluids with particulates, high viscosity heavy oil or slurries, high temperatures, or cryogenic conditions.

However, metal-seated ball valves have higher torque value. Meanwhile, a very small amount of leakage as per standard is allowable due to its metal-to-metal design.

How to Choose

In conclusion, for clean fluid within general temperature range ( normally less than 250°C), a soft-seated ball valve is an economical option.

While, for severe conditions with high temperature, abrasive solids or high viscosity, you should choose the more durable one, a metal-seated ball valve, considering the cost of downtime and maintenance.

Seat Material Options and applications:

Soft Seat:

PTFE-Made from Virgin Teflon, this is the most common sealing material; its chemical compatibility is excellent for almost all media. Temperatures range: -50°F to 400°F.

RPTFE-15% glass reinforced PTFE, suitable for temperatures from -50°F to 450°F. Chemical resistance is compatible with virgin PTFE with a better wear factor. The majority of our ball valves conform to this standard.

Carbon Filled PTFE- 25% Carbon Graphite with 75% PTFE, this material offers a wide temperature range with better wear resistance than standard RPTFE. Good for steam service from 50°F to 450°F.

Delrin-Delrin is a very rigid material that can withstand pressures of up to 5000psi depending on valve size and temperatures ranging from -50°F to 180°F.

PEEK-PEEK is for high temperature and pressure service, suitable for tobacco and nuclear service. Temperature range: -70°F to 550°F

Nylon-Special Nylon seats are offered for higher pressure and lower temperature service. They can be used in high-pressure air, oil, and other gas media but are not suited for strong oxidizing agents. Temperature range: -30°F to 200°F

Metal Seat:

Stellite Seat Surface-Recommended for service with severe flashing or hydraulic shock, abrasive media, or where possible, trapped metal may exist. Relia valve metal seats are hand lapped to the ball as individually matched sets, assuring line contact between valve ball and seats, resulting in smooth operation and tight shut off class. Relia valve offers metal-seat ball valves in different classes of shut off, including Class IV, V, and VI.

Cr3C2-suitable up to 815°C, good corrosion resistance.

WC-Co-Tungsten, Carbon Cobalt, Excellent corrosion resistance.