Side Entry, Top Entry, Welded Body Ball Valve

Ball valves are key devices to shut off and regulate the flow of a fluid (oil, gas, steam, etc.). According to the ball valve body construction, ball valves can often be divided into side-entry ball valves, top-entry ball valves,welded body ball valves.

Side Entry, Top Entry & Fully Welded Ball Valve Comparation

| Advantage | Disadvantage | |

| Side Entry | Easy to assemble, trim components are easy to align. | It needs to be disassembled from the pipeline for trim repair. |

| Top Entry | In-line maintenance | It is the heaviest of the quarter-turn ball valve and slightly more expensive than other ball valve designs. |

| Fully Welded | No leakage paths through body and bonnet joint | It is difficult to maintain. |

Side Entry Ball Valve

Side entry ball valves are valves that have an assembled ball from the side part. It is usually assembled in two pieces or a three-piece body. Each part of the body is assembled by a bolt/stud, just like joining two pieces of flanges.

Side entry ball valves are also easy to assemble, and the trim components are also easy to align. Another advantage of the side entry type is its fast delivery time. Side entry ball valves are the most commonly used ball valve types and should be the default choice to specify a ball valve type on a data sheet.

Side entry leads to the necessity of removing the valve from the pipe for trim repair and maintenance.

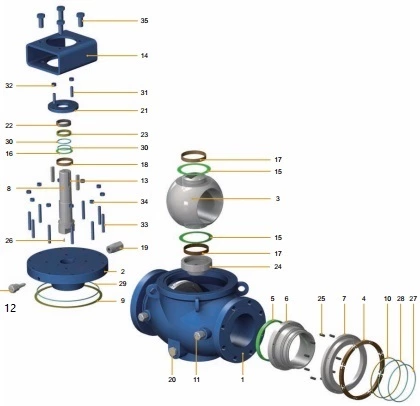

Side entry trunnion ball valve explosive view

Top Entry Ball Valve

Top entry ball valves are valves that assemble their balls from the top side part. They do not need to be removed from the pipe for maintenance. Furthermore, the top entry ball valves' construction allows for minimal bolted connections, reducing the possibility of a leak path.

The top entry ball valve is just like a globe valve that has a body and bonnet except the trim part utilizes a ball type. It comprises one single body.

Top entry ball valves are typically made of cast steel. Because it is made of cast steel, it will require additional NDE testing to ensure that there are no casting defects.

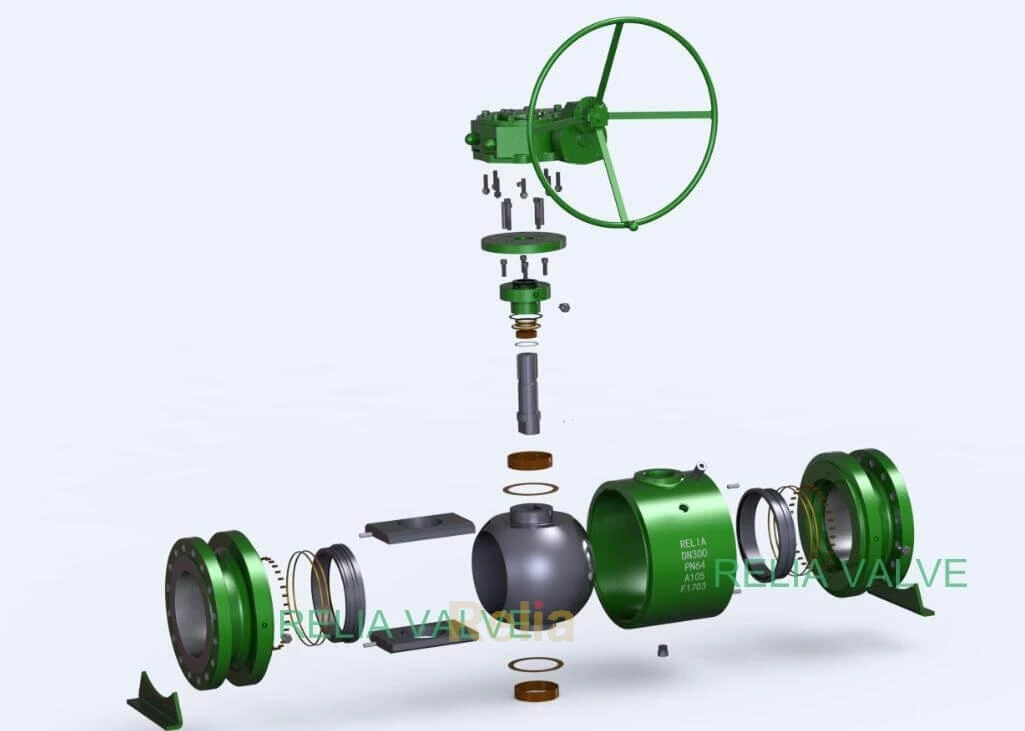

Top entry trunnion ball valve explosive view

The top entry ball valves are usually used in applications that require minimal disassembly for in-line maintenance of their internal parts. Therefore, it’s very common to use top entry ball valves in high pressure applications that require infrequent maintenance, such as HIPPS (High Integrity Pressure Protection System) valves etc.

The advantages of the top entry ball valves are that their construction allows minimal thread connection, so that it will also minimize possible leak paths.

Keep in mind that the face-to-face dimensions are usually longer than the side-entry ball valves.

Welded Body Ball Valve

Welded body ball valves are valves where the body and bonnet are assembled completely welded so that there are no leak paths through bolt connections etc. It’s not possible to do maintenance on the valve in the field.

The welded body ball valve is usually used in underground or buried applications where maintenance is not expected, such as gas transmission, subsea applications etc.

Welded body ball valves are usually made from forged steel to ensure the fine quality of the raw material. The welded joint is subject to an NDT test in the event of a defect.

Welded body ball valve explosive view