Anti-static Device In Ball Valves

What is an anti-static device in a ball valve?

An anti-static device used in a ball valve is to reduce the static charge generated on the ball due to friction. It is used to protect the valve against a spark that may ignite the fuel flowing through it.

An anti-static device is the basic and mandatory design for ball valves. During the operation of the valve, the constant friction between the ball and the soft seat will generate static electricity. Static electricity can cause a spark, which could ignite the flammable fluid inside the valve and cause a fire hazard.

Anti-static Device for Floating Ball Valve

Why does the static come out?

Static electricity is a common physical phenomenon. When two different materials are rubbed together, an electrostatic charge is generated due to the transfer of electrons. An object that receives electrons is negatively charged, and an object that loses electrons is positively charged. This process is called triboelectric charging. In theory, as long as the two objects of friction are compared, one side is more likely to lose electrons while the other side is more likely to obtain electrons. Two objects of different materials can generate static electricity by friction. Friction between two objects of the same material will not produce static electricity.

How does an anti-static device work?

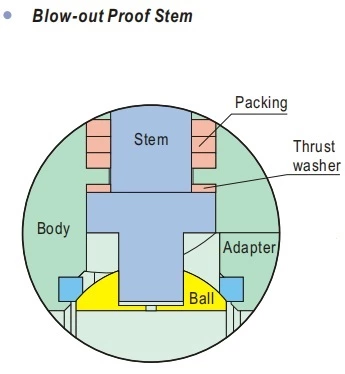

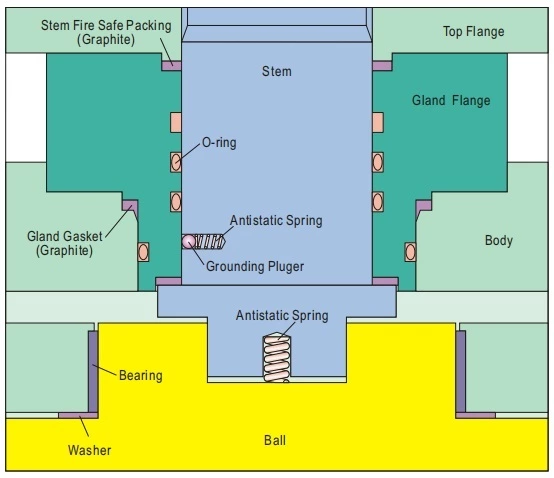

An anti-static device was invented for the ball valve to get rid of the hidden danger. In the picture shown below, the anti-static devices are located between the ball and stem, and the body is composed of a spring and a stainless steel ball, which make sure that all the metal parts of the ball valve are grounded. In this way, the static charge could be transmitted from ball to stem, and then from stem to body and ground, to prevent any potential fire hazard caused by static charge inside the valve.

Anti-static Device for Trunnion Mounted Ball Valves

Is your anti-static device acceptable?

How to know if an anti-static device is qualified? Let's refer to the most frequently used standards, API 6D and BS 5153.

API 6D specifications

Anti-static design

If the buyer asks for it, the valves shall have an anti-static device and be tested according to clause C.5.

Anti-static testing (clause C.5)

The electrical resistance between the obturator and the valve body and between the stem/shaft and the valve body shall be measured using a D.C. power source not exceeding 12 V. The resistance shall be measured on dry valves before pressure testing and shall not exceed 10 Ω.

At least 5% of the valves in the order shall be tested.

Ball Valve Anti-static Inspection

BS 5351 Specifications

Anti-static design

Valves shall incorporate an anti-static feature that ensures electrical continuity between stem and body of valves DN 50 or smaller, or between ball, stem and body of larger valves.

You can use a conductive stem seal as long as it's not the only way to make the stem anti-static.

Anti-static testing

Valves shall be type-tested, with the testing being carried out on new dry "as-built" valves of each type after pressure testing. The test for electrical continuity shall be carried out after the test valve has been operated at least five times. It shall then be demonstrated that the discharge path between components, as specified in 8.11, has electrical continuity with a resistance not exceeding 10 Ω from a power source not exceeding 12 V.

Relia anti-static device ball valve

All Relia ball valves have incorporated anti-static devices between the ball stem and the stem and body, respectively, comprising a small metal ball which is spring-loaded and retained in a drilled hole in the stem and gauged to protrude slightly from the stem to engage the ball or the body, respectively. The design and tests for anti-static completely meet API 6D and BS 5351 specifications.