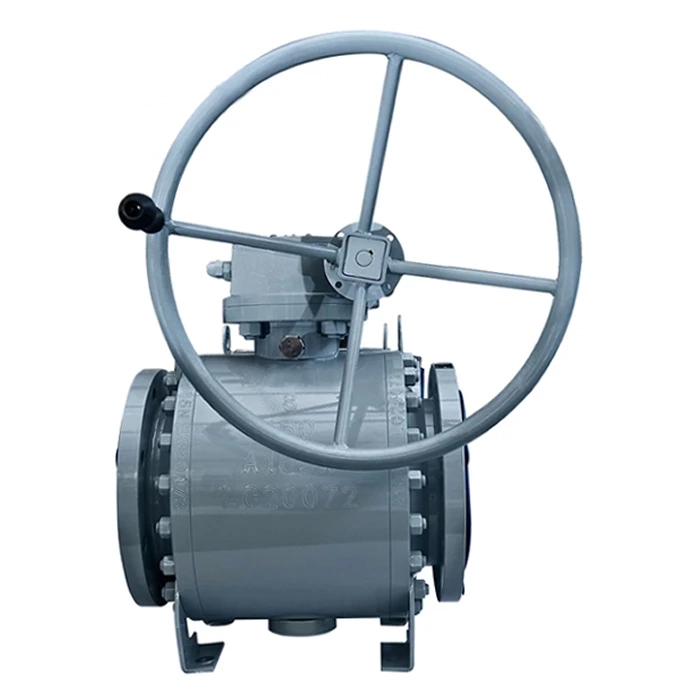

API 607 Ball Valve

API 607 Ball valves are designed and tested to ensure that they can withstand fire exposure without excessive leakage, maintaining their pressure-containing capability and operability after the fire event.

API 607 specifies fire type-testing requirements and a fire type-test method for quarter-turn valves and other valves equipped with nonmetallic seats.

- Valve Type

- Ball Valve

- Standard

- API 607

- Design Feature

- Fire Safe

- Certificate

- API 607

1. Fire Test Requirements

- Closed Valve Testing: The valve is completely filled with water under pressure and subjected to fire for a period of 30 minutes.

- Heat Exposure: The valve is exposed to an environmental temperature of 750°C to 1000°C (1400°F to 1800°F) to ensure that the seat and sealing areas are exposed to high burn temperatures.

- Leakage Measurement: Internal and external leakage is recorded during the burn period and after cool-down.

2. Performance Criteria

- Through-seat Leakage: During the burn period, the maximum allowable through-seat leakage is specified in the standard.

- External Leakage: Both during the burn period and after cool-down, the average external leakage of the valve in the open position shall not exceed specified limits.

- Operability: After the fire test, the valve must still be operable and able to cycle from fully closed to fully open against the test pressure.

3. Test Conditions

- Test Pressure: The test pressure during the burn period is set at 0.2 MPa (30 psig) for nonmetallic seated valves rated Class 150 and Class 300. For all other valves, the test pressure is 75% of the maximum permissible seat working pressure at 20°C (70°F).

- Test Fluid: The valve is filled with water during the test.

- Thermocouples and Calorimeters: Used to monitor the intensity of heat input and ensure that the valve is properly enveloped in flames.

4. Qualification of Other Valves

- Representative Testing: Instead of testing each nominal size and pressure rating, a valve of a given design can be tested to qualify other valves of the same design within certain limits (e.g., up to twice the nominal size or pressure rating of the test valve).

- Materials of Construction: The materials of construction of the pressure-retaining envelope of the valve can qualify other materials within the same generic classification (ferritic, austenitic, duplex).

5. Reporting Requirements

- Test Report: A detailed test report must be provided, including information on the test conditions, valve description, leakage measurements, and observations made during the test.

6. Additional Considerations

- Valve Design: The valve design must accommodate the test conditions, including provisions for pressure relief and thermal expansion.

- Insulation: The valve and any components used during testing (except as part of the valve design) must not be protected with insulation material.

- Safety: Adequate safety precautions must be taken during the fire test to protect personnel and equipment from potential hazards.

Leave Us Your Info

Could you please kindly fulfill the following information when enquiring:

Valve type (ball, gate, globe, check etc.), valve size, pressure class, valve material, and end connection (flanged, butt welding etc.)