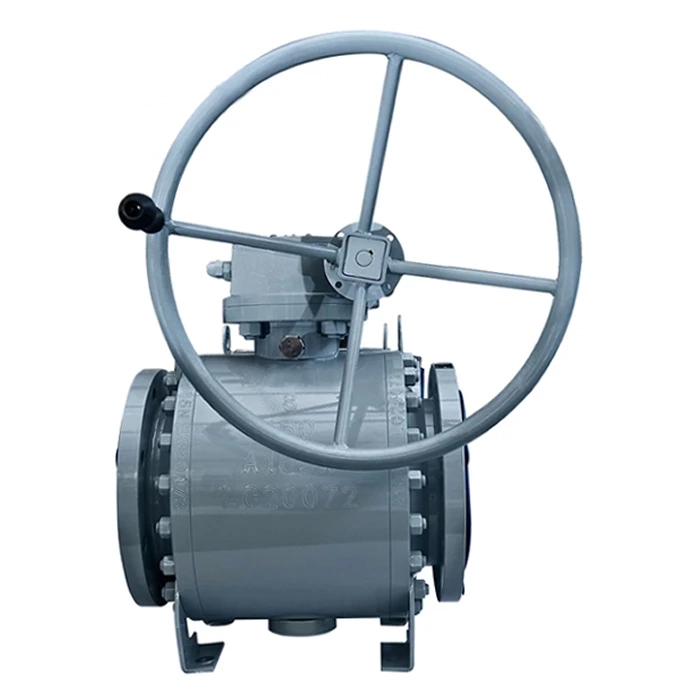

API 608 Ball Valve

API 608 ball valves are reliable in petroleum, petrochemical, and industrial applications by addressing safety, material integrity, and operational durability.

- Valve Type

- Ball Valve

- Standard

- API 608

- End Connections

- Flanged or Welded

- Unit Price

- $60-50000

1. Scope and Applicability

- Valve Types: Floating (seat-supported) and trunnion-mounted ball valves.

- End Connections:

- Flanged (DN 15–600 / NPS ½–24).

- Butt-welding (DN 15–600 / NPS ½–24).

- Socket-welding (DN 8–50 / NPS ¼–2).

- Threaded (DN 8–50 / NPS ¼–2).

- Pressure Classes:

- Flanged/Butt-welding: Classes 150, 300, 600.

- Socket-welding/Threaded: Classes 150, 300, 600, 800.

- Bore Sizes: Full bore, single reduced bore, double reduced bore.

2. Design Requirements

- Flow Passageway: Must allow passage of a cylinder with diameters specified in Table 3 (e.g., full bore for DN 50: 49 mm).

- Body Construction:

- Wall thickness conforms to ASME B16.34 (Standard Class).

- Flange dimensions follow ASME B16.5.

- Welded flanges require full penetration butt welds.

- Antistatic Design: Ensures electrical continuity (≤10 ohms resistance) between ball, stem, and body (critical for explosive environments).

- Stem and Ball:

- Stem-to-ball connection must withstand 20 N·m torque or twice the manufacturer’s maximum torque.

- Ball must be solid one-piece construction unless otherwise agreed.

- Packing Glands:

- Adjustable glands accessible without disassembly.

- No vertically split glands; gland bolts must not exceed 1/3 ultimate tensile strength under compression.

- Operation:

- Manual levers or gear operators with ≤360 N input force.

- Position stops for open/closed positions; clockwise closing.

- Lockable devices (for open/closed positions) optional.

3. Material Requirements

- Shell: Materials per ASME B16.34 (e.g., carbon steel, stainless steel).

- Trim: Ball, stem, and seats match or exceed shell material properties. Corrosion-resistant options (e.g., NACE MR 0103 compliance) available.

- Bolting: Intermediate strength (ASME B16.5 minimum) or higher grades if specified.

- Seals/Gaskets: Compatible with valve’s pressure-temperature ratings (e.g., PTFE, R-PTFE, metal seats).

4. Testing and Inspection

- Pressure Testing: Per API 598 (shell, seat, and closure tests).

- Fire Testing: Complies with API 607 if specified (fire-resistant seats with secondary metal seals).

- Inspection: Manufacturer examination mandatory; optional purchaser inspection.

5. Marking and Identification

- Mandatory Markings:

- "API 608" on identification plate.

- Ring joint groove number (if applicable).

- Directional arrows for unidirectional valves.

- Material Identification: Austenitic stainless steel/nickel alloy plates welded or pinned.

6. Packaging and Shipping

- Protection:

- Drain test fluid; apply rust inhibitors.

- Protective end covers/plugs (removable; prevent installation with covers).

- Position: Shipped fully open unless design restricts.

7. Optional Features (Purchaser-Specified)

Lockable devices, NACE compliance, fire-tested seats, export packaging, spare parts lists.

Leave Us Your Info

Could you please kindly fulfill the following information when enquiring:

Valve type (ball, gate, globe, check etc.), valve size, pressure class, valve material, and end connection (flanged, butt welding etc.)