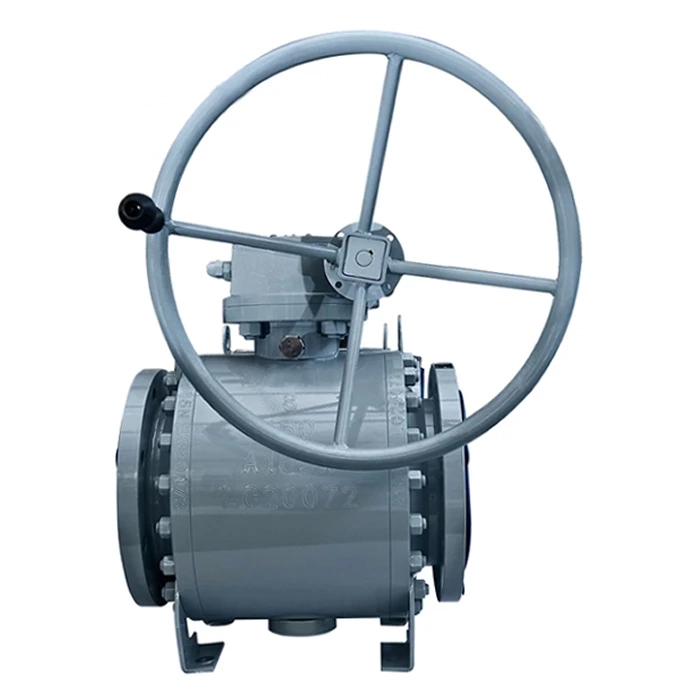

API 6D Valves

API 6D Valves (ball, check, gate, and plug valves) meet the rigorous requirements of the petroleum and natural gas industries in terms of safety, reliability, and performance.

- Standard

- API 6D

- Size

- 2"-48"

- Pressure Rating

- Class 150-2500

- Unit Price

- $58-60000

- Certificate

- API 6D

1. Types of Valves

- Ball Valves: Valves with a spherical closure member that rotates on an axis perpendicular to the direction of flow.

- Check Valves: Valves with a closure member that responds automatically to block fluid in one direction.

- Gate Valves: Valves with a closure member that moves in a plane perpendicular to the direction of flow.

- Plug Valves: Valves with a cylindrical or conical closure member that rotates about an axis perpendicular to the direction of flow.

2. Design and Materials

- Design Standards: Valves must conform to internationally recognized design codes such as ASME BPVC, Section VIII, or EN standards.

- Material Requirements: Metallic materials must meet specified chemical composition, mechanical properties, and impact testing requirements. Nonmetallic materials such as seals must have defined physical property requirements.

3. Manufacturing Processes

- Process Control: Manufacturers must have a quality management system in place to ensure conformance with API 6D.

- Welding: Welding procedures and welders must be qualified in accordance with industry standards.

- Nondestructive Examination (NDE): Various NDE methods, including radiographic, ultrasonic, magnetic particle, and liquid penetrant testing, are required for different valve components and manufacturing stages.

4. Testing

- Pressure Testing: Valves must undergo hydrostatic shell and seat tests to ensure they can withstand specified pressures without leakage.

- Gas Testing: High-pressure gas shell and seat tests may be required to demonstrate the valve's performance under extreme conditions.

- Torque/Thrust Testing: The maximum torque or thrust required to operate the valve must be measured and documented.

5. Marking and Documentation

- Marking: Valves must be marked with the manufacturer's name, material grade, pressure rating, size, and other relevant information.

- Documentation: Manufacturers must provide detailed documentation, including material test reports, NDE records, pressure test reports, and assembly drawings.

6. Additional Features and Options

- Double Block and Bleed (DBB): Valves can be designed with DBB features to isolate two pressure sources and bleed/vent pressure between the sealing elements.

- Double Isolation and Bleed (DIB): DIB valves provide two sealing elements to a single pressure source and allow bleeding/venting between the sealing elements.

- Fire Testing: Valves can be qualified for fire testing in accordance with API 6FA or API 607 to ensure they can withstand fire exposure without leakage.

- Extended Hydrostatic Shell Test: By agreement, valves can undergo hydrostatic shell tests at pressures higher than specified in the standard.

- Custom Design Features: The purchaser can specify various custom design features, such as special end connectors, drain connectors, lifting provisions, and antistatic devices.

Leave Us Your Info

Could you please kindly fulfill the following information when enquiring:

Valve type (ball, gate, globe, check etc.), valve size, pressure class, valve material, and end connection (flanged, butt welding etc.)