Double Block and Bleed Ball Valve

Double block and bleed ball valves (DBB) are generally single valves with two seats, providing a seal against pressure from both ends of the valve and internal self-relieving seats.

API 6D definition: DBB valve is a single valve with two seating surfaces that, in the closed position, provide a seal against pressure from both ends of the valve, with a means of venting/bleeding the cavity between the seating surfaces.

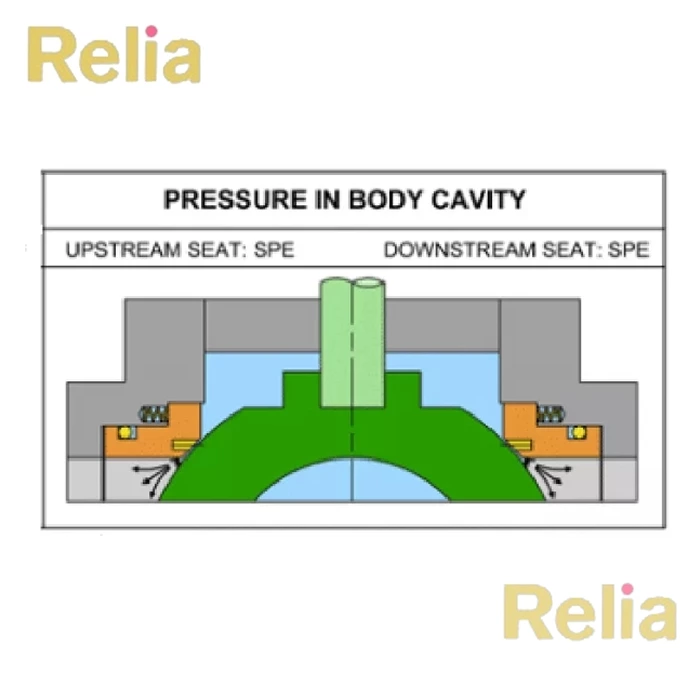

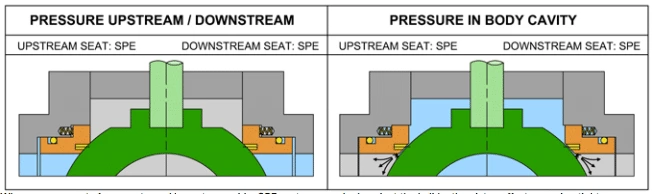

Double block and bleed seats (DBB) are generally internal self-relieving seats.

Double Block: When the ball is in the closed position, each seat seals off the process medium independently at the same time between the up and down stream.

Bleed: When the ball is in closed position and the pressure rating of the trapped medium gets 1.33 times the line pressure, the trapped medium gets released between the seats automatically.

There are two types of double block and bleed ball valves:

Trunnion Ball Valves with Double Block and Bleed (Type 1)

The trunnion mounted ball valve may trap the media in the body cavity when the operator closes the valve. The trapped fluid expands and the pressure increases in the cavity when heated. If the cavity pressure is 1.33 times the line pressure, the trapped fluid will push the seat of the downstream side away from the ball by rising pressure against the spring load. When this happens, the pressure gets released.

Type 2: A Single Valve with Twin Balls: Double Block and Bleed

Trunnion Ball Valve with Twin Balls

Floating Ball Valve with Twin Balls

Leave Us Your Info

Could you please kindly fulfill the following information when enquiring:

Valve type (ball, gate, globe, check etc.), valve size, pressure class, valve material, and end connection (flanged, butt welding etc.)