Fully Welded Ball Valve

Fully welded ball valves are made of high-quality forged steel. Fully welded trunnion mounted ball valves with an extended stem are ideal for underground buried service or pipeline.

Relia Valve is a fully welded ball valve manufacturer in China with API 6D, API 607 and CE certificates. We have a full range of fully welded ball valves for onshore and offshore topside applications in the oil and gas transmission industry. We supply all our welded ball valves at the best price.

The fully welded ball valve can be butt welded ends or flanged ends according to the customer's request.

The body is made from three forged parts, and its all-welded construction has fewer leak paths than bolted-body ball valves. All welding is performed according to ASME Section IX, and all welding processes are qualified. The welding for the valve body is to be performed with non-destructive tests.

A cavity-relief valve is installed in the body to relieve any overpressurization encountered during service or testing. By pressurizing the body cavity, the integrity of sealing surfaces can be monitored without pressure in the pipeline.

- Size

- 2" - 48"

- Pressure Rating

- Class 150 -2500

- End Connections

- Flanged, Butt Welded

The fully welded ball valve design combines the maximum strength at the minimum weight, as well as a high resistance to pipeline internal and external stress.

Body Material:

Carbon steel, optional partial or full CRA overlay on the wetted area

Low alloy carbon steel, optional partial or full CRA overlay on the wetted areas.

Stainless Steel

Duplex or Superduplex stainless steel

Seat Material:

Soft or Metal Seat

Operator

Lever or gear

Pneumatic

Hydraulic

Electric

Gas Over Oil

Main Features:

Fully welded body

Forged body

Trunnion mounted ball valve

Soft, or metal-seated

DBB - Automatic cavity relief to prevent overpressure in the body cavity (self-relieving seats)

DIB seat (optional)

Extended stem for underground burried service

Non-destructive tests (X-ray etc. ) are performed as per ASME on weld joints of the body.

Pups pieces - unpon request

Stem grease injectors - unpon request

Seat grease injection - unpon request

Standard Specifications

| Design | API 6D, API 6DSS, ASME B16.34, ISO 14313, ISO 17292 | Pressure Rating | ASME B16.34, EN 1092-1, ISO 17292 |

| Wall Thickness | ASME B16.34, ASME VIII Div. I, ISO 17292 | Face to Face | API 6D, ASME B16.10 Long pattern |

| BW Ends | ASME B16.25 | Flange Ends | ASME B16.5/ASME B16.47 |

| Fire Safe | API 607, API 6FA, BS 6755, ISO 10497-5 | Figitive Emission | ISO 15848/1 |

| Leakage rate | ISO 5208 rate A soft seated, rate D metal seated | Valve Test | API 6D/API 598 |

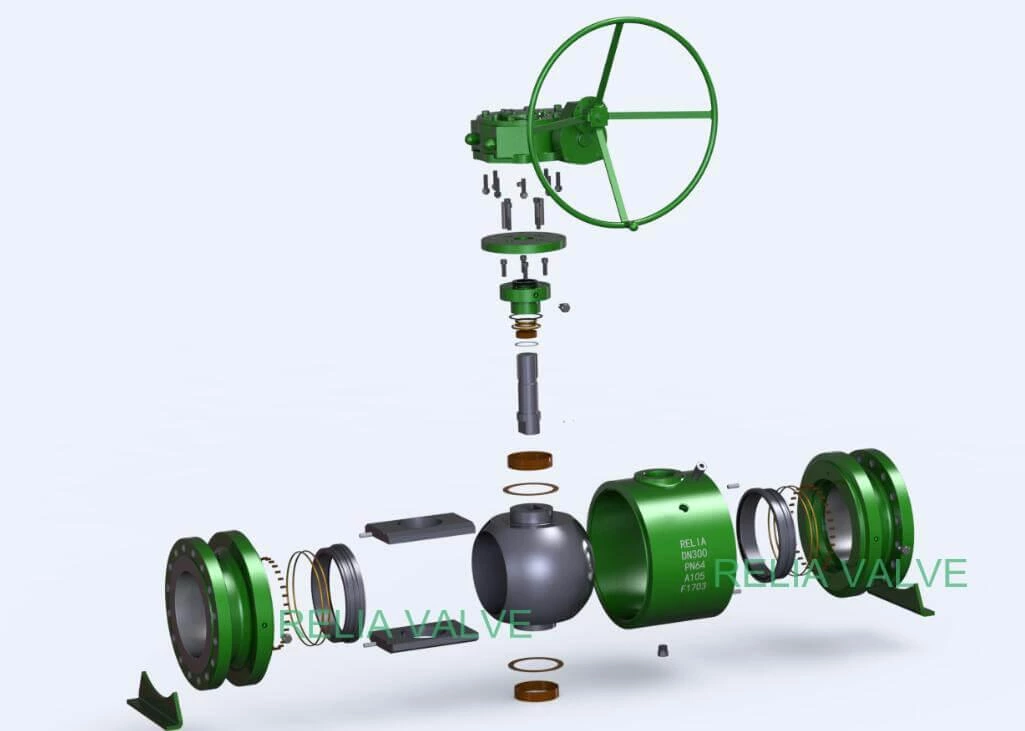

Fully Welded Ball Valve Explosive Drawing

Leave Us Your Info

Could you please kindly fulfill the following information when enquiring:

Valve type (ball, gate, globe, check etc.), valve size, pressure class, valve material, and end connection (flanged, butt welding etc.)