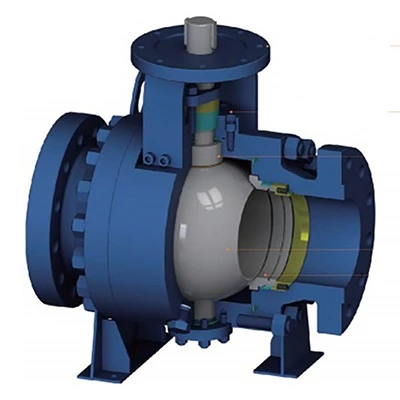

Metal Seated Ball Valve

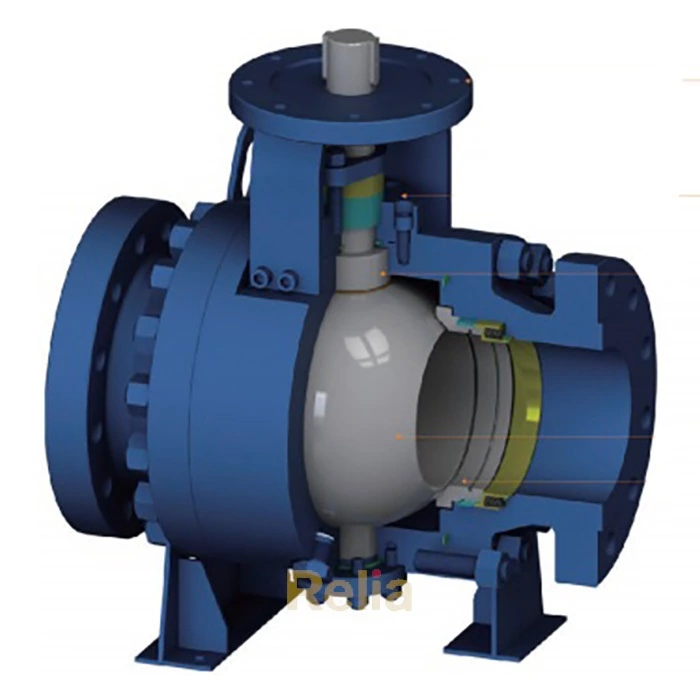

Metal seated ball valve for severe services: high temperature, hight pressure and abrasive service; metal seated floating and trunnion mounted ball valves with zero leakage, meeting En 12266-1 rate A.

We have side entry and top entry metal seated ball valves. Metal seated ball valves are ideal for isolation purpose.

Relia Metal seated ball valves have advantages, such as excellent corrosion & wear resistance, tight shut-off, smooth control, low torque, wide temperature & pressure range, as well as stability under pressure.

Relia Valve is a metal seated ball valve manufacturer & supplier in China, with API 6D, API 607 and CE Certificate, providing best price metal seat ball valves.

The seat ring and ball are precisely machined and lapped to match ball, creating a positive seal for bubble-tight performance. Metal seated ball valve provides long service life with outstanding fugitive emissions performance and low operating torques in even the toughest applications.

- Size

- 1/2" - 40"

- Pressure Rating

- Class 150 - 2500

- Temperature Range

- -29 - 650℃

Metal Seated Ball Valve for High-temperature Service

Metal-seated ball valves incorporate a metal-to-metal seal between the seats and ball of the valve assembly. Our high-temperature metal-seated ball valves are engineered, constructed, and tested with careful metallurgical selection of all valve parts, using special surface finishing and treatments, hard coatings, and thorough analyses of mechanical strength and thermal expansion, ensure that our high-temperature metal-seated ball valves are a proven choice for the industries' toughest and most demanding applications.

Fire-safe is guaranteed without exception

Metal or hard graphite seats are resistant to great heat, while flexible graphite is used for other sealing components like gland packing and flange gaskets to ensure that no part of the valve is damaged by high temperatures. In addition, since electric current can flow between the components, an anti-static device is unnecessary.

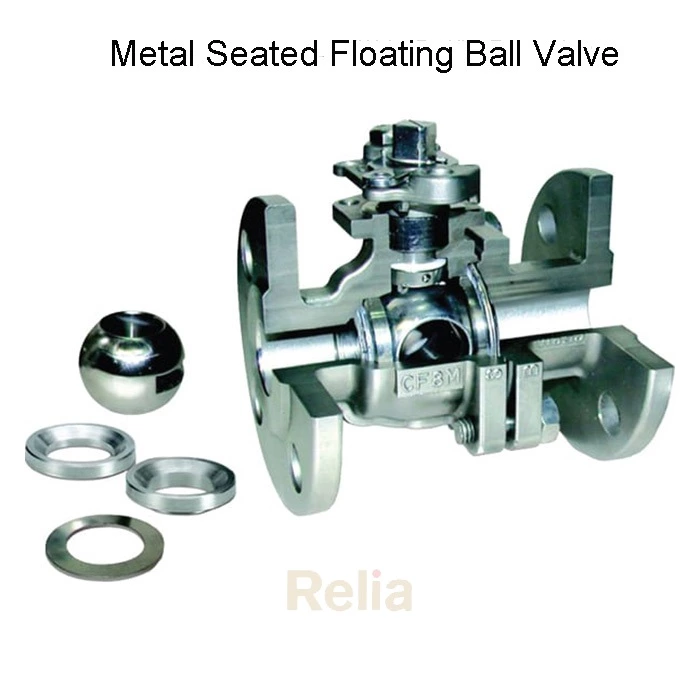

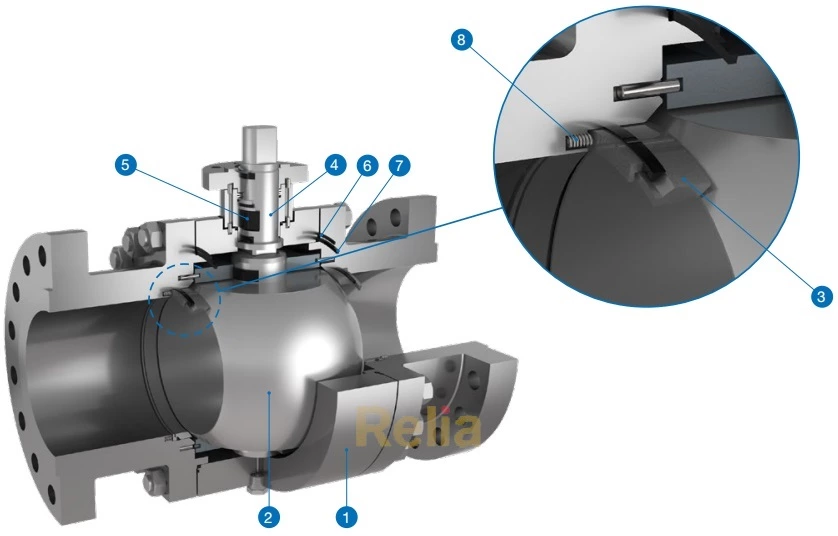

Metal Seated Floating Ball Valve for High Temperature

The spring-loaded uni-directional seat spring provides flexibility for thermal expansion for stabilizing operation Seat.

Coating Material (on Ball/Seat): Stellite 6, Cr3C2 (Chromium Carbide), Cr3C2 (Chromium Carbide)

Seal: Expanded Graphite

Spring: Inconel 718

Temperatures: 60° C to 650° C (-76° F to+1200° F).

Shut Off CLASS: BS-EN 12266-1 Rate C, FCI 70-2Class V (Rate B, Class VI upon request)

Service: steam, thermal oil, clean gases, filtered fluids.

Metal seated floating ball valves for high temperature

Metal seated floating ball valves for high temperature

General Features:

- Floating ball valve

- Bi-directional

- Fire safe

- Anti static

- Split body

Metal Seated Floating Ball Valve Drawing

Material Specifications

| Item | Part Name | ASTM | DIN | ||

| Carbon steel | Stainless steel | Carbon steel | Stainless Steel | ||

| 1 | Body | A216 WCC/A352 LCC | A351 CF8M | 1.0619 / 1.6220 | 1.4408 |

| 2 | Ball | A182 F316+Cr-Carbide | 1.4401+Cr-Carbide | ||

| 3 | Seats | A182 F316+Cr-Carbide | 1.4401+Cr-Carbide | ||

| 4 | Stem | XM-19 | XM-19 | ||

| 5 | Stem Packing | Graphite | Graphite | ||

| 6 | Body Seal 1 | Graphite | Graphite | ||

| 7 | Body Seal 1 | Graphite | Graphite | ||

| 8 | Spring Seat | Inconel X 750 | Inconel X 750 | ||

Note:

1. For body seal and seat seal, graphite is used for fire safety purposes as per API 607/API 6FA.

2. Other construction materials for various services are available upon request.

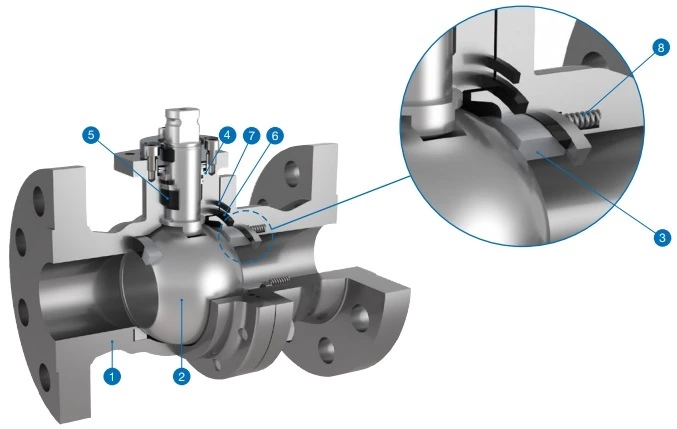

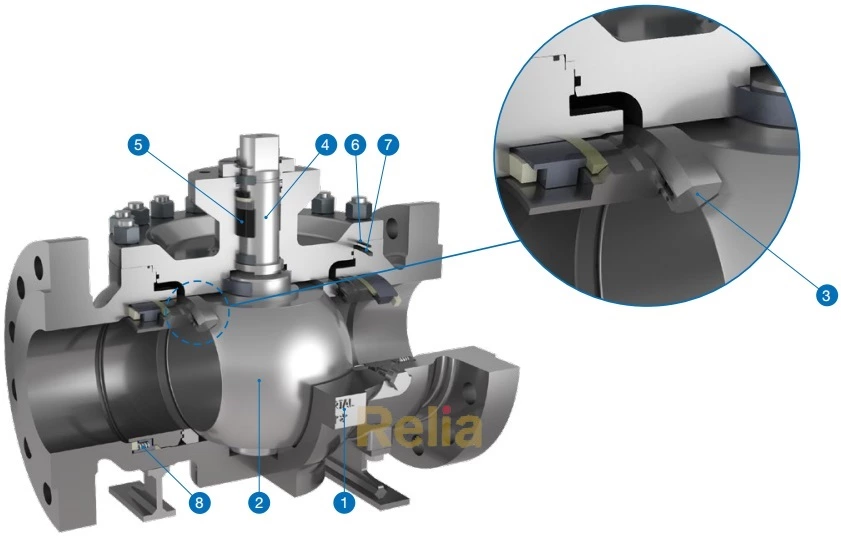

Metal Seated Trunnion Ball Valve for High Temperature

The bi-directional, split 2-piece seat provides freedom for thermal expansion of the ball without jamming, even at extreme temperatures.

Coating Material ( on Ball/Seat): Cr3C2 (Chromium Carbide), Cr3C2 (Chromium Carbide), Stellite 6

Advantage: Split seat to avoid thermal expanion jack

Seal: Expanded graphite

Temperature: -60° C + 650° C (-76° F +1200° F)

Leakage Class: BS-EN 12266-1 Rate C, FCI 70-2Class V (Rate B, Class VI upon request)

Service: steam, thermal oil, clean gases, filtered fluids

Metal seated trunnion mounted ball valve for high temperature

General Feature:

- Trunnion mounted ball valve

- Double block and bleed

- Self-cavity pressure relief

- Bidirectional

- Spring loaded seats

- Fire safe

- Anti static

Metal Seated Trunnion Mounted Ball Valve Drawing

Material Specifications

| Item | Part Name | ASTM | DIN | |||

| Carbon Steel | Stainless Steel | Carbon Steel | Stainless Steel | |||

| 1 | Body | A216 WCC/A352 LCC | A351 CF8M | 1.0619 / 1.6220 | 1.4408 | |

| 2 | Ball | A182 F316+Cr-Carbide | 1.4401+Cr-Carbide | |||

| 3 | Seats | A182 F316+Cr-Carbide | 1.4401+Cr-Carbide | |||

| 4 | Stem | XM-19 | XM-19 | |||

| 5 | Stem Packing | Graphite | Graphite | |||

| 6 | Body Seal 1 | Graphite | Graphite | |||

| 7 | Body Seal 1 | Graphite | Graphite | |||

| 8 | Spring Seat | Inconel X 750 | Inconel X 750 | |||

Note:

1. For body seal and seat seal, graphite is used for fire safety purposes as per API 607/API 6FA.

2. Other construction materials for various services are available upon request.

3. The trunnion mounted metal seated ball valve is ideal for high tempeture, high pressure application.

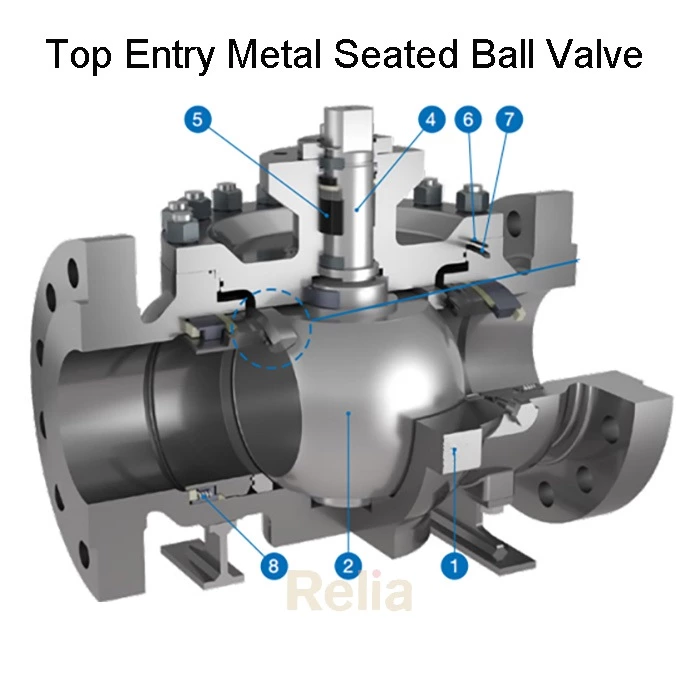

Top Entry Metal Seated Ball Valve Drawing

Material Specifications

| Item | Part Name | ASTM | DIN | |||

| Carbon Steel | Stainless Steel | Carbon Steel | Stainless Steel | |||

| 1 | Body | A216 WCC/A352 LCC | A351 CF8M | 1.0619 / 1.6220 | 1.4408 | |

| 2 | Ball | A182 F316+Cr-Carbide | 1.4401+Cr-Carbide | |||

| 3 | Seats | A182 F316+Cr-Carbide | 1.4401+Cr-Carbide | |||

| 4 | Stem | XM-19 | XM-19 | |||

| 5 | Stem Packing | Graphite | Graphite | |||

| 6 | Body Seal 1 | Graphite | Graphite | |||

| 7 | Body Seal 1 | Graphite | Graphite | |||

| 8 | Spring Seat | Inconel X 750 | Inconel X 750 | |||

Note:

1. For body seal and seat seal, graphite is used for fire safety purposes as per API 607/API 6FA.

2. Other construction materials for various services are available upon request.

3. The trunnion mounted metal seated ball valve is ideal for high tempeture, high pressure application.

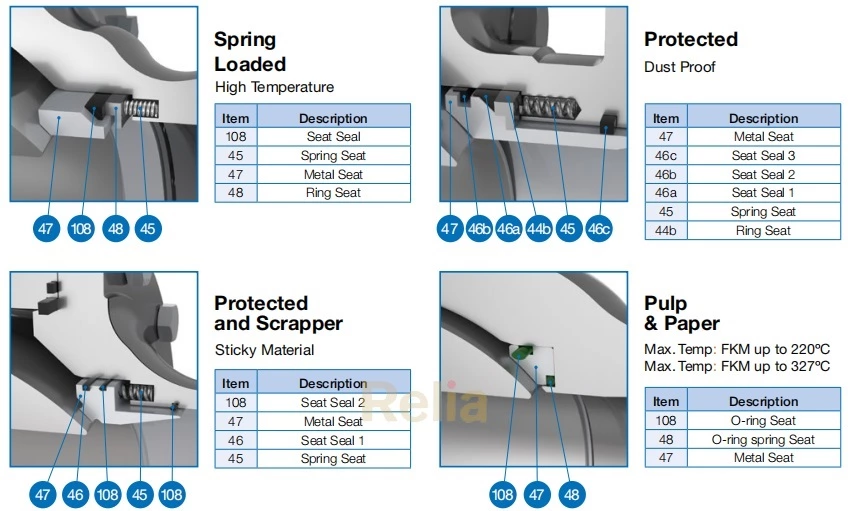

Metal Seated Ball Valve for Abrasion Resistance

The metal-to-metal seat ball valve is designed for abrasive and erosion service and is equipped with a specially designed scraper design seat and high hardness material.

The valve ball and seat of the ball valve are made of very hard material and are not easily damaged by the service fluid.

Bidirectional sealing and the scraper seat design enable the metal-to-metal seat ball valve to maintain the sealing and long-term operation.

These are to prevent damage from service fluid and erosion from inside passage.

Shut off class: BS-EN 12266-1 Rate A, FCI 70-2Class V (Rate B, Class VI upon request), or Zero Leakage.

Metal seated ball valve for abrasive application

Metal seated ball valve for abrasive applicationSeat Models:

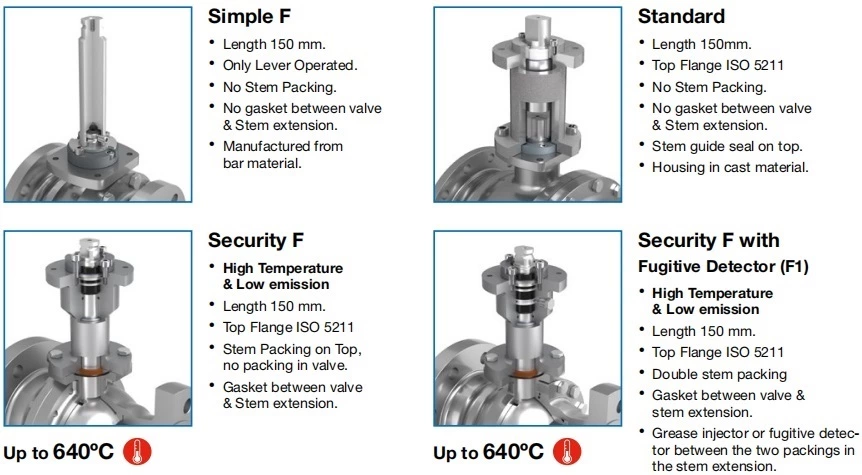

Stem Extension for High Temperature Ball Valve

Meatal Seat Material Properties & Applications

| Coating Material | Coating Method | Hardness (HRc) | Suitable Temperature | Application |

| Stellite 6 | HVOF & Fused | 37-42 | 815℃ | - Liquid + Gaseous media with partially entrained particles / solids (moderate operating cycle) - Excellent wear resistance / good corrosion resistance - Wide temperature range |

| Tunsten Carbide | HVOF | 69-72 | 427℃ | - Liquid + Gaseous media with partially entrained particles / solids (high operating cycles) - Excellent abrasion resistance / good corrosion resistance |

| Hard Nickel Alloy | HVOF & Fused | 58-62 | 500℃ | - Liquid + Gaseous media with partially entrained particles / solids (high operating cycles) - Excellent abrasion resistance |

HVOF- High velocity oxygen fuel coating is a cutting edge fully automated coating technology which gives uniform layer of coating over the trim parts.

Industries application

As one of the top metal-seated ball valve manufacturers, Relia valve has experience in serving the Oil & Gas, Petroleum, Petrochemical, Chemical, Power Generation, Pulp & Paper, and Mining industries.

Petrochemical

The P-series metal seated ball valves handle applications in corrosive, abrasive, slurry, extreme pressure, catalyst, chemical, and petrochemical applications.

Mining for Metals and Minerals

M-series metal-seated ball valves handle applications in mining, slurry transport, autoclave (HPAL), and heavy slurry.

Power generation

PG-Series metal-seated ball valves handle applications in power generation. They feature in-line repairable, automated relief valve systems, solids, ash-handling blocks, and isolation valves.

Refining

The R-Series metal seated ball valves handle specific applications from isolation to welded end valves, catalyst handling, RF-Series for high alloy customized valves, and D-Series for double block and bleed designs.

Leave Us Your Info

Could you please kindly fulfill the following information when enquiring:

Valve type (ball, gate, globe, check etc.), valve size, pressure class, valve material, and end connection (flanged, butt welding etc.)