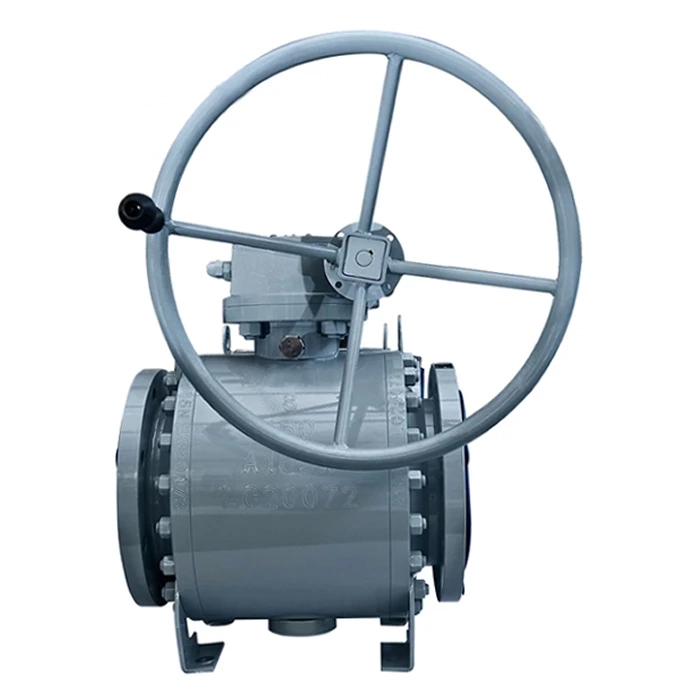

Top Entry Ball Valve

Top entry ball valves with one-piece body design allow in-line maintenance. Get Best price from top entry trunnion mounted ball valve manufacturers in China.

In-line repair or replacement of valve internal components without dismantling it from the pipe line gives the convenience of in-line repair or replacement.

Quality top entry ball valves are trunnion mounted ball valves with bi-directional sealing with two independent floating seats. The top entry ball valve features a double block and bleed, fire-safe design, and anti blow-out stem.

Top entry ball valves are usually made from cast steel. Relia performs additional NDE tests on the valve body to ensure that there are no casting defects.

- Size

- 2" - 48"

- Pressure Rating

- Class 150 - 2500

- End Connections

- Flanged, Welding Ends etc.

Relia top entry type ball valve in the pipeline is simple and rapid demolition, making maintenance convenient. When the top entry ball valve in the pipeline fails to repair, you do not have to remove the ball valve from the pipeline; just remove the flange bolts and nuts, the valve cover and stem assembly are removed from the valve body; and then remove the ball and valve seat assembly.

Top-entry ball valves are typically used in process systems where in-line maintenance is preferred over full valve removal. As such, it is common for top entry ball valves to be used in high-pressure applications that require infrequent maintenance, like high-integrity pressure protection system (HIPPS) valves.

Structure:

One Piece Body

Trunnion Mounted Ball Valve

Body Material:

Carbon Steel, Low Temperature Carbon Steel, Stainless Steel, Duplex Steel etc.

Seat Material:

Soft seat or metal seat

Bore Type:

Full bore or reduced bore

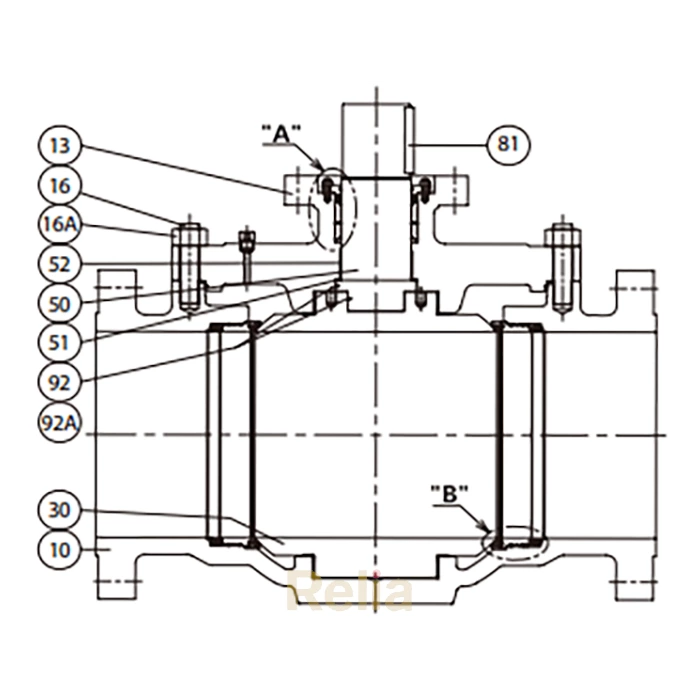

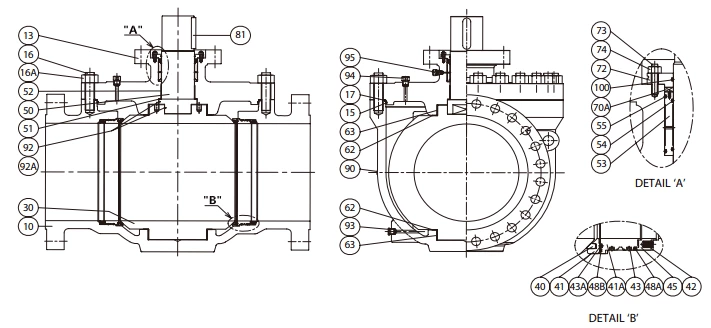

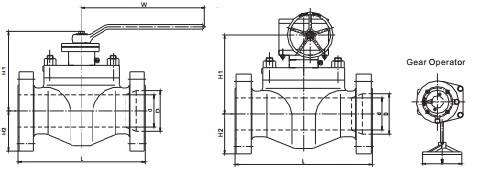

Top Entry Ball Valve Drawing

Materil Specifications

| No. | PART NAME | Carbon Steel | Low Temp. CS | Stainless Steel |

| 10 | BODY | A216-WCB | A352 LCB | A351 CF8M |

| 13 | BONNET | A216-WCB | A352 LCB | A351 CF8M |

| 15 | BONNET O-RING | FKM | FKM-GLT | FKM |

| 16 | BONNET BOLT | A193 B7 | A320 L7 | A193 B8M |

| 16A | BONNET NUT | A194 2H | A194 4 | A194 8M |

| 17 | BONNET GASKET | INHIBITED FLEXIBLE GRAPHITE | ||

| 30 | BALL | A182 F316 | ||

| 40 | SEAT | RTFE OR NYLON OR PEEK | ||

| 41 | SEAT HOLDER | 316 STAINLESS STEEL | ||

| 41A | SEAT BACK-UP RING | 316 STAINLESS STEEL | ||

| 42 | SEAT SPRING | INCONEL X750 | ||

| 43 | O-RING | FKM | FKM-GLT | FKM |

| 43A | O-RING | FKM | FKM-GLT | FKM |

| 45 | SPRING HOLIDER | 316 STAINLESS STEEL | ||

| 48A | FIRE SAFE SEAL | INHIBITED FLEXIBLE GRAPHITE | ||

| 48B | FIRE SAFE SEAL | INHIBITED FLEXIBLE GRAPHITE | ||

| 50 | STEM | 316 STAINLESS STEEL | ||

| 51 | STEM THRUS BEARING | 316 STAINLESS STEEL+PTFE | ||

| 52 | STEM BEARING | 316 STAINLESS STEEL+PTFE | ||

| 53 | STEM BUSH | 316 STAINLESS STEEL+ENP | ||

| 54 | BUSH INNER O-RING | FKM | FKM-GLT | FKM |

| 55 | BUSH INNER O-RING | FKM | FKM-GLT | FKM |

| 62 | THRUST BEARING | 316 STAINLESS STEEL+PTFE | ||

| 63 | BEARING | 316 STAINLESS STEEL+PTFE | ||

| 70A | STEM FIRE SAFE SEAL | INHIBITED FLEXIBLE GRAPHITE | ||

| 72 | STEM COVER | A105N | A350 LF2 | A182 F316 |

| 73 | STEM COVER BOLT | A193 B7 | A320 L7 | A193 B8M |

| 74 | STEM COVER NUT | A194 2H | A194 4 | A194 8M |

| 80 | T-BAR TUBE | A53 GALVANIZED | ||

| 81 | KEY | ANNSI 1025 | ||

| 82 | STOP PLATE | 316 STAINLESS STEEL | ||

| 83 | T-BAR SOCKET | A395+BLACK PAINT | ||

| 84 | T-BAR BOLT | A193 B8M | ||

| 85 | STOP BOLT | A193 B8M | ||

| 87 | WORM GEAR OPERATOR | COMMERCIAL | ||

| 88 | GEAR MOUNTING BOLT | A193 B7 | A320 L7 | A193 B8M |

| 89 | GEAR MOUNTING NUT | A194 2H | A194 4 | A194 8M |

| 90 | NAME PLATE | 316 STAINLESS STEEL | ||

| 92 | ANTI-STATIC DEVICE | 316 STAINLESS STEEL | ||

| 92A | ANTI-STATIC PLUNGER | 316 STAINLESS STEEL | ||

| 93 | DRAIN PLUG | 316 STAINLESS STEEL | ||

| 94 | VENT VALVE | 316 STAINLESS STEEL | ||

| 95 | INJECTOR | 316 STAINLESS STEEL | ||

| 96 | INJECTOR | 316 STAINLESS STEEL | ||

| 100 | WIPER SEAL | NBR | ||

Dimensions & Weight

Class 150-600 Top Entry Ball Valve Dimensions & Weight, API 6D

| Size | D | L | H1 | H2 | W | Weight |

| inch | mm | mm | mm | mm | mm | kg |

| 1-1/2" | 38 | 241 | 209 | 70 | 400 | 30 |

| 2" | 51 | 292 | 195 | 110 | 400 | 38 |

| 3" | 76 | 356 | 240 | 110 | 750 | 80 |

| 4" | 102 | 432 | 280 | 175 | 1000 | 150 |

| 6" | 152 | 559 | 305 | 195 | *300 | 296 |

| 8" | 203 | 660 | 400 | 280 | *300 | 438 |

| 10" | 254 | 787 | 435 | 285 | *500 | 601 |

| 12" | 305 | 838 | 440 | 320 | *600 | 625 |

| 14" | 337 | 889 | 505 | 340 | *600 | 1230 |

| 16" | 387 | 991 | 590 | 410 | *600 | 1535 |

| 18" | 438 | 1092 | 700 | 445 | *600 | 2135 |

| 20" | 489 | 1194 | 775 | 510 | *600 | 2640 |

| 24" | 591 | 1397 | 840 | 640 | *600 | 3960 |

Class 900 Top Entry Ball Valve Dimensions & Weight, API 6D

| Size | D | L | H1 | H2 | W | Weight |

| inch | mm | mm | mm | mm | mm | kg |

| 1-1/2" | 38 | 305 | 215 | 80 | 400 | 40 |

| 2" | 51 | 368 | 200 | 120 | 750 | 52 |

| 3" | 76 | 381 | 240 | 130 | 1000 | 87 |

| 4" | 102 | 457 | 280 | 175 | 1500 | 160 |

| 6" | 152 | 610 | 350 | 220 | *300 | 385 |

| 8" | 203 | 737 | 390 | 260 | *400 | 560 |

| 10" | 254 | 838 | 480 | 310 | *600 | 820 |

| 12" | 305 | 965 | 538 | 410 | *600 | 1125 |

Class 1500 Top Entry Ball Valve Dimensions & Weight, API 6D

| Size | D | L | H1 | H2 | W | Weight |

| inch | mm | mm | mm | mm | mm | kg |

| 1-1/2" | 38 | 305 | 220 | 90 | 400 | 40 |

| 2" | 51 | 368 | 205 | 120 | 750 | 60 |

| 3" | 76 | 470 | 210 | 125 | 1000 | 115 |

| 4" | 102 | 546 | 245 | 160 | *300 | 194 |

| 6" | 146 | 705 | 335 | 255 | *400 | 580 |

| 8" | 194 | 832 | 427 | 340 | *500 | 752 |

| 10" | 241 | 991 | 502 | 381 | *600 | 1195 |

| 12" | 289 | 1130 | 533 | 438 | *600 | 2170 |

Leave Us Your Info

Could you please kindly fulfill the following information when enquiring:

Valve type (ball, gate, globe, check etc.), valve size, pressure class, valve material, and end connection (flanged, butt welding etc.)