Trunnion Ball Valve

We are trunnion ball valve manufacturer and supplier in China, providing API 6D trunnion ball valve with bubble-tight shut-off and low operating torques.

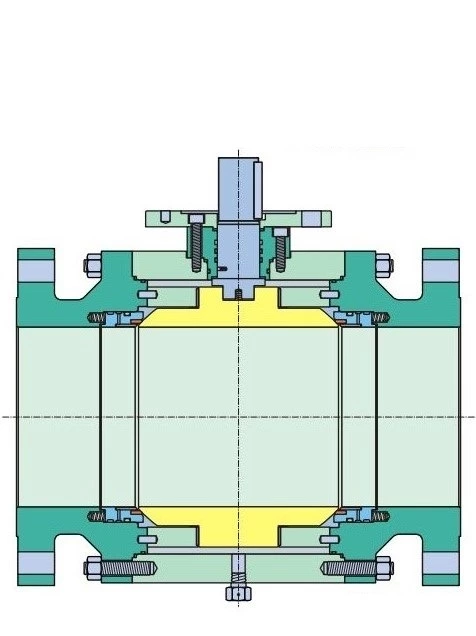

Trunnion ball valve is combined with trunnion-mounted ball and unique spring-loaded seat. Trunnion ball valve is available in cast steel trunion ball valve and forged steel trunnion ball valve.

Features:

- Double block and bleed

- Self-relieving seat

- Side entry, 2 or 3 pieces

- Zero leakage

Options:

- DIB seats

- Low fugitive emission

- Top entry

- Fully welded

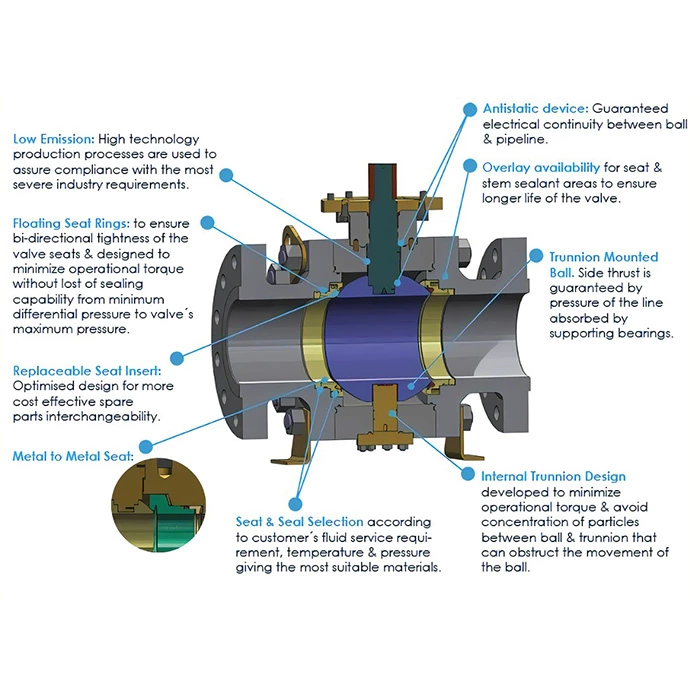

Trunnion Ball Valve Design Features

1. Gerneral Design

In the trunnion ball valve, the ball is fixed by a trunnion, and the seat rings are floating, free to move against the ball along the valve center line. The trunnion and bearings absorb the side load created by the pressure acting on the ball.

At low pressure, the seat-tight sealing is ensured by the preload of the springs acting on the seat rings. Along with the pressure increasing, medium pressure pushes the seat rings against the ball to provide additional load for tight sealing.

The ball and stem are independent of each other to minimize the effect of the side thrust generated by the pressure acting on the ball.

The ball is fixed by a trunnion

(for small size trunnion ball valve)

The ball is fixed by a retaining plate

(for large size and high pressure trunnion ball valve)

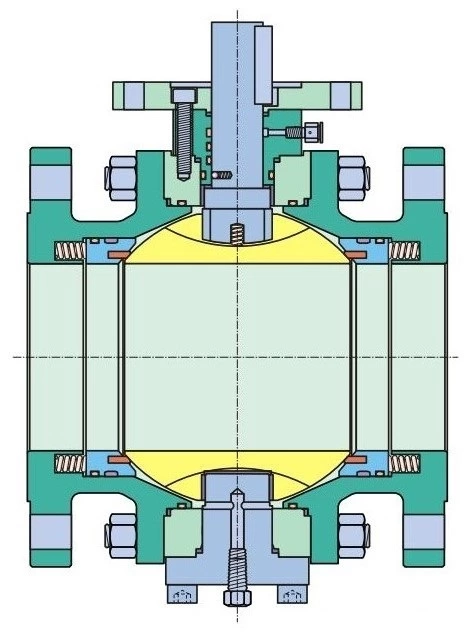

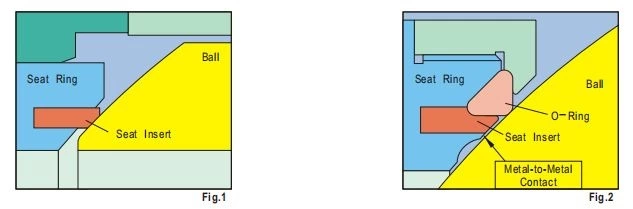

2. Seat Design

The standard seat design of the trunnion ball valve is a primary soft seal and a secondary metal-to-metal seal.

The seat insert is designed as a pressed-in type, which is easy to maintain. (Fig. 1) Optional design with primary metal-to-metal seal and secondary soft seal seat design is also available upon request. (Fig. 2)

Primary soft seal, and secondary metal to metal seal (PMSS seat)

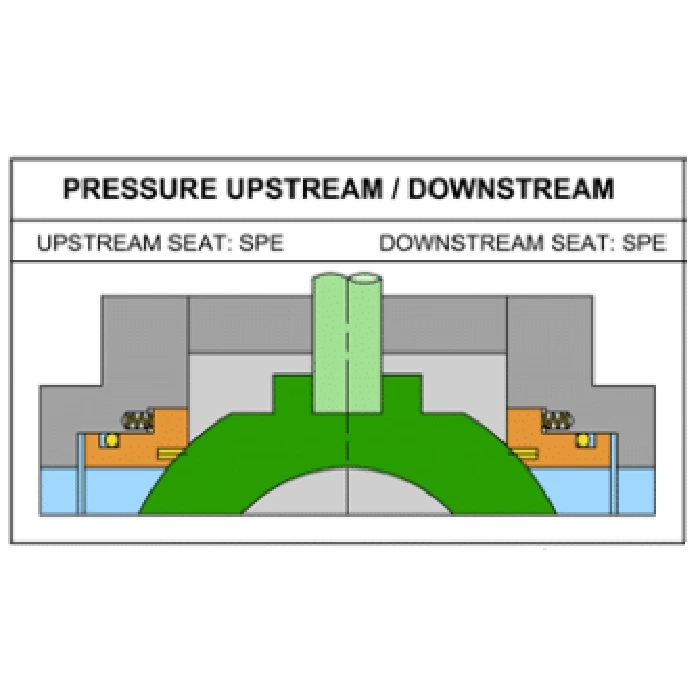

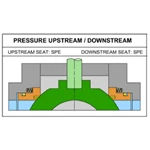

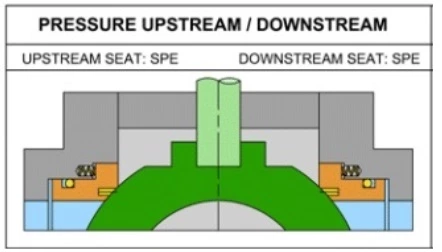

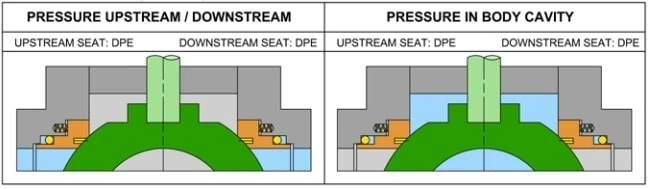

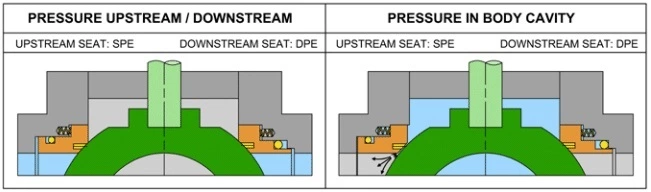

3. Double Block and Bleed

Double block: both seats are single piston seats; when the ball is closed, each seat seals off the process medium independently from the upstream and downstream;

Bleed: the trunnion ball valve has a drain and vent valve, which allows bleeding of the trapped cavity pressure through the drain or vent valve.

Double block and bleed trunnion ball valve

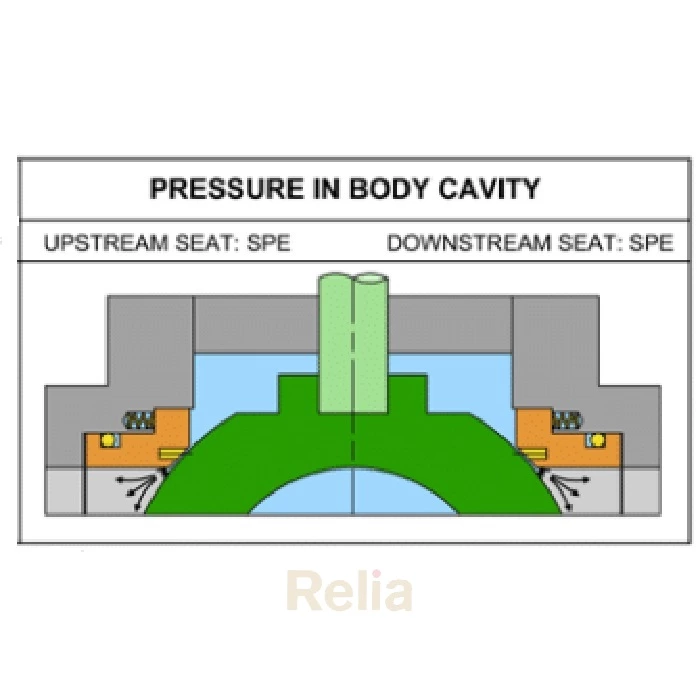

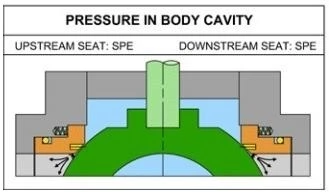

4. Self Relieving Seats (for overpressure in the body cavity)

In a trunnion ball valve, both seats are single piston seats, medium pressure in the body cavity creates a resultant thrust to push the seat rings away from the ball.

The design permits the automatic release of any overpressure in the body cavity when the valve is fully open or fully closed.

Self relieving seat trunnion ball valve

5. Double Isolation and Bleed (Optional)

DIB 1: Both seats are double piston seats; each seat seal off the fluid from the upstream and downstream. A safety valve is needed as a cavity pressure relief device to reduce overpressure build-up in the body cavity.

DIB 1 Trunnion ball valve

DIB 2: One seat is a single piston seat, and the other is a double-piston seat; the double-piston seat seals off the fluid from the upstream and downstream, and the single piston seals off the fluid from upstream.

DIB 2 trunnion ball valve

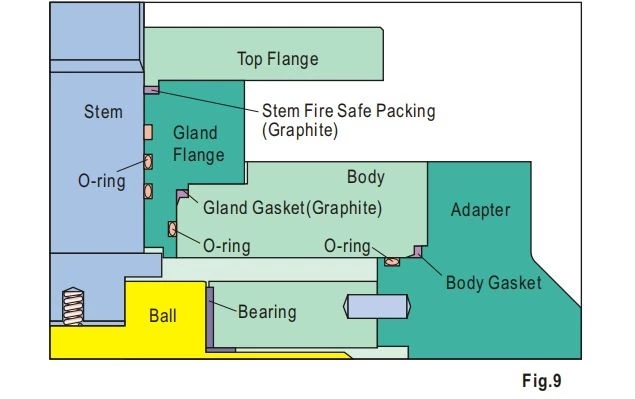

6. Low Fugitive Emission

In our trunnion ball valve, accurate machining of stem, gland, and bonnet sealing surfaces with double sealing (O-ring primary seal plus graphite gasket seal) ensures low emission, which complies with the most severe pollution-control regulations, such as API 641.

7. AED O-Ring

When the trunnion ball valve is used in high-pressure gas applications (e.g., hydrocarbon gas service under class 600 and above), the gas may be absorbed into the molecular structure of elastomeric O-rings. If the valve is subjected to sudden decompression, the rapidly expanding gas may destroy the O-rings. Special AED O-rings or lip seals suitable for such service conditions are available upon request to avoid this possibility.

a) External leakage prevention

In the trunnion ball valve, all the possible external leakage points between the stem and gland flange, gland flange and body, and adapter are sealed with a primary O-ring, then a secondary graphite gasket. When the fire burns out the primary O-ring seal, the secondary graphite gasket seal can still prevent the process fluid from external leakage. (Fig. 9)

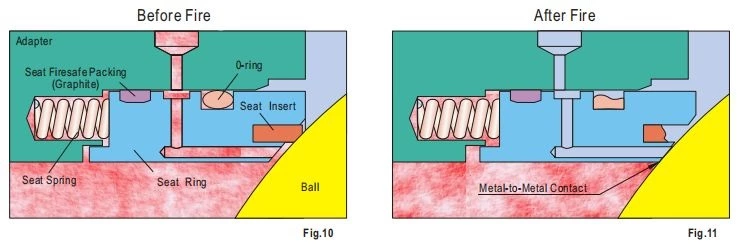

b) Internal leakage prevention

For a trunnion ball valve, when the fire burns out the primary O-ring seal between the floating seat ring and adapter, also the seat insert between the seat ring and ball, the secondary graphite seal between seat ring and adapter, and seat ring & ball metal to metal contact pre-loaded by spring will minimize the internal process medium leakage. (Fig. 10,11)

Internal leakage prevention

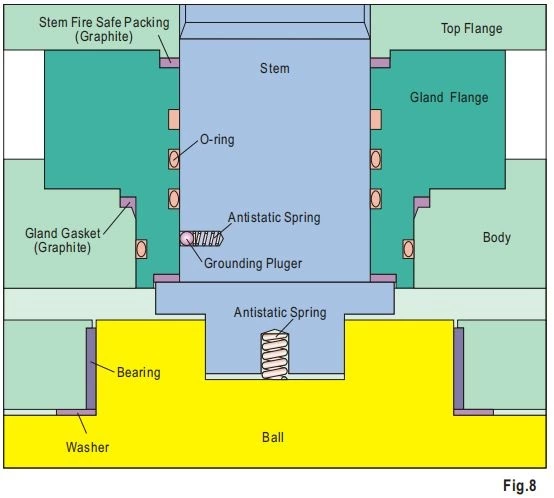

9. Anti-static Device

Spring plus graphite-type anti-static devices are applied between the ball, stem, gland flange, and body to keep the electrical continuity between all the metallic components and ensure the resistance is lower than the most severe service requirement. (Fig. 8)

10. Blow-out Proof Stem

In a trunnion ball valve, the stem is made separately from the ball with an integral T-type round shoulder retained by the gland (other designs are available on request). (Fig. 8)

Anti-static device, blow-out proof stem

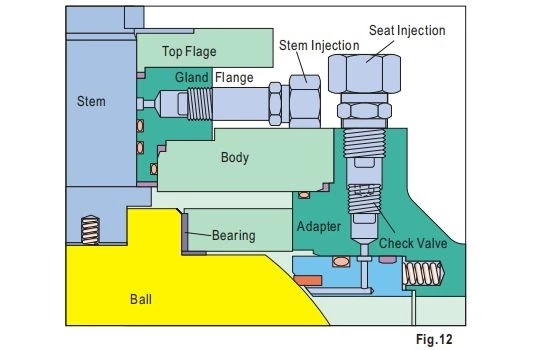

11. Emergency Sealant Injection System

6” and larger trunnion ball valve (or smaller sizes on request) is equipped with sealant injection located at the stem and seat area. The injection is integrated with a check valve to provide backup sealing. Also, a check valve is equipped at the front of the seat sealant injection to avoid blowing out in case of wrong operation. When the soft sealing materials (seat inserts and o-rings) are damaged, and leakage happens by fire or other accident, the sealant can be injected through the injection fittings. (Fig. 12)

12. Ball Seat Alignment

Mechanical stops are equipped on all trunnion ball valves to ensure the ball is never over-rotated.

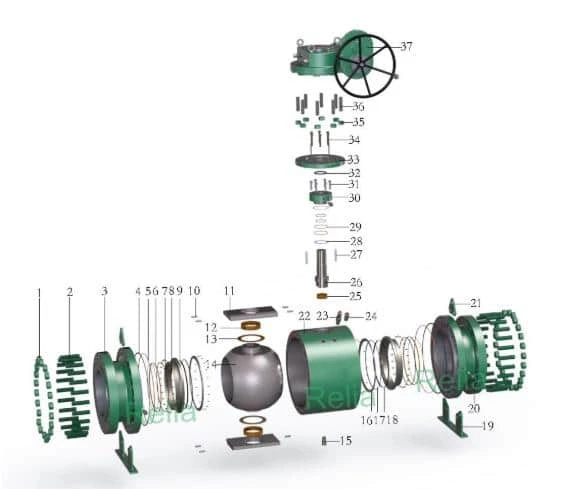

Trunnion Ball Valve Drawing & Material Specifications

Trunnion Ball Valve Drawing

(Sdie entry, 3 piece, forged steel)

Material Specifications

| Part No. | Part Name | A105 Body | LF2 Body | F316 Body |

| 1 | Nut | A194 2H | A194 7 | A193 B8 |

| 2 | Bolt | A193 B7 | A320 L7 | A182 F316 |

| 3 | Bonnet | ASTM A105 | A350 LF2 | A182 F316 |

| 4 | Gasket | SS304+Graphite | SS316+Graphite | SS316+Graphite |

| 5 | O-Ring | Viton AED | Viton AED | Viton AED |

| 6 | O-Ring | Viton AED | Viton AED | Viton AED |

| 7 | Graphite | SS304+Graphite | SS316+Graphite | SS316+Graphite |

| 8 | Spring | Inconel X-750 | Inconel X-750 | Inconel X-750 |

| 9 | Seat Ring | A105+ENP | A182 F316 | A182 F316 |

| 10 | Pin | Carbon Steel | Stainless Steel | Stainless Steel |

| 11 | Trunnion | A105+ENP | A182 F316 | A182 F316 |

| 12 | Bearing | C.S+Graphite | S.S+Graphite | S.S+Graphite |

| 13 | Gasket | SS304+Graphite | SS316+Graphite | SS316+Graphite |

| 14 | Ball | A105+ENP | A182 F316+ENP | A182 F316+ENP |

| 15 | Drain Plug | A182 F316 | A182 F316 | A182 F316 |

| 16 | A105+ENP | Stainless Steel | Stainless Steel | Stainless Steel |

| 17 | Seal Ring | Viton AED | Viton AED | Viton AED |

| 18 | Seat Ring | PEEK/Nylon | PEEK/Nylon | PEEK/Nylon |

| 19 | Feet | Carbon Steel | Carbon Steel | Carbon Steel |

| 20 | Injection Plug | Stainless Steel | Stainless Steel | Stainless Steel |

| 21 | Lifting Lug | Carbon Steel | Carbon Steel | Carbon Steel |

| 22 | Body | ASTM A105 | A350 LF2 | A182 F316 |

| 23 | Safety Valve | Carbon Steel | Carbon Steel | Carbon Steel |

| 24 | Relief Valve | Carbon Steel | Stainless Steel | Stainless Steel |

| 25 | Trunnion Bearing | C.S+Graphite | S.S+Graphite | S.S+Graphite |

| 26 | Stem | A182 F6A | A182 F316 | A182 F316 |

| 27 | Key | Carbon Steel | Carbon Steel | Carbon Steel |

| 28 | Thrust Washer | PTFE | PTFE | PTFE |

| 29 | O-Ring | Viton AED | Viton AED | Viton AED |

| 30 | Stuffing Box | ASTM A105 | A350 LF2 | A182 F316 |

| 31 | Bolt | A193 B7 | A320 L7 | A193 B8 |

| 32 | Packing | SS304+Graphite | SS316+Graphite | SS316+Graphite |

| 33 | Adapter | ASTM A105 | A350 LF2 | A182 F316 |

| 34 | Bolt | A193 B7 | A320 L7 | A193 B8 |

| 35 | Nut | A194 2H | A194 7 | A194 8 |

| 36 | Bolt | A193 B7 | A320 L7 | A193 B8 |

| 37 | Worm Gear | Ductile Iron | Ductile Iron | Ductile Iron |

Related Information

Valve body material selection guide

Ball valve seat material selection guide

Leave Us Your Info

Could you please kindly fulfill the following information when enquiring:

Valve type (ball, gate, globe, check etc.), valve size, pressure class, valve material, and end connection (flanged, butt welding etc.)