API 6D Swing Check Valve

API 6D swing check valves are designed for use in high-pressure oil, gas, and pipeline systems to prevent reverse flow.

- Low Pressure Drop: Full-bore design minimizes flow resistance.

- Durability: Robust construction for high-pressure and high-temperature services.

- Maintenance-Friendly: Bolted-cover designs allow easy access to internal components.

1. Design Features

-

Disc and Hinge Mechanism:

- A swinging disc (clapper) mounted on a hinge pin or pivot arm.

- The disc swings freely in the flow path, opening with forward flow and closing automatically when flow stops or reverses.

- Gravity and flow dynamics ensure closure (no external actuation required).

-

Full-Bore Design:

- Typically full-port (full-bore) to minimize pressure drop and turbulence, critical for high-flow applications.

-

Body Construction:

- Bolted cover or pressure seal, depending on size and pressure class.

- Designed to meet ASME B16.34 pressure-temperature ratings.

-

Seat Design:

- Metal-to-metal seating for tight shutoff (standard).

-

End Connections:

- Flanged ends per ASME B16.5/B16.47 or butt-weld ends per ASME B16.25.

- Optional hub, threaded, or other connections as specified.

-

Face-to-Face Dimensions:

- Compliant with API 6D/ASME B16.10 standards.

2. Material Specifications

-

Body and Trim:

- Carbon steel (e.g., ASTM A216 WCB), stainless steel (e.g., ASTM A351 CF8M), or alloy materials (e.g., Duplex, Inconel) for corrosive or high-temperature services.

- Hinge pins and disc arms are often made of hardened stainless steel for wear resistance.

-

Seat and Disc:

- Hard-faced surfaces (e.g., Stellite) for erosion resistance in high-velocity or abrasive services.

-

Non-Metallic Seals:

- Elastomers (NBR, Viton) or PTFE for sealing, compliant with NACE MR-0175 for sour service if required.

3. Performance and Testing

-

Pressure Testing:

- Shell Test: Hydrostatically tested to 1.5× the valve’s pressure rating.

- Seat Test: Tested for leakage at 1.1× rated pressure (liquid) or 0.6 MPa (gas).

- Optional low-pressure gas test (0.05–0.1 MPa) for fugitive emissions compliance.

-

Fire-Safe Design:

- Optional compliance with API 6FA or API 607 for fire-safe performance (metal seats and fire-resistant materials).

-

Cyclic Testing:

- Valves may undergo endurance testing to verify repeated opening/closing reliability.

4. Optional Features

-

Counterweighted Disc:

- For vertical installation, a counterweight ensures proper closure against gravity.

-

Spring-Assisted Closure:

- Accelerates disc closure to prevent water hammer in fast-flow systems.

-

Drain and Vent Plugs:

- For pipeline draining or pressure relief.

-

Lifting Lugs or Eye Bolts:

- Facilitate safe handling and installation.

-

Locking Device:

- Allows the valve to be locked open/closed for maintenance.

-

Coating/Internal Lining:

- Internal epoxy coatings or corrosion-resistant linings for harsh environments.

5. Compliance and Certification

-

API 6D Requirements:

- Design, manufacturing, testing, and documentation comply with API 6D (24th/25th edition).

- Optional API Monogram for certified valves.

-

Additional Standards:

- NACE MR-0175 for sour service (H₂S environments).

- ISO 14313 (equivalent international standard)

6. Advantages of API 6D Swing Check Valves

- Low Pressure Drop: Full-bore design minimizes flow resistance.

- Durability: Robust construction for high-pressure and high-temperature services.

- Maintenance-Friendly: Bolted-cover designs allow easy access to internal components.

7. Applications

- Oil and gas pipelines, refineries, petrochemical plants, and offshore platforms.

- Suitable for horizontal or vertical upward flow (orientation-specific designs available).

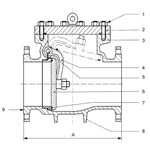

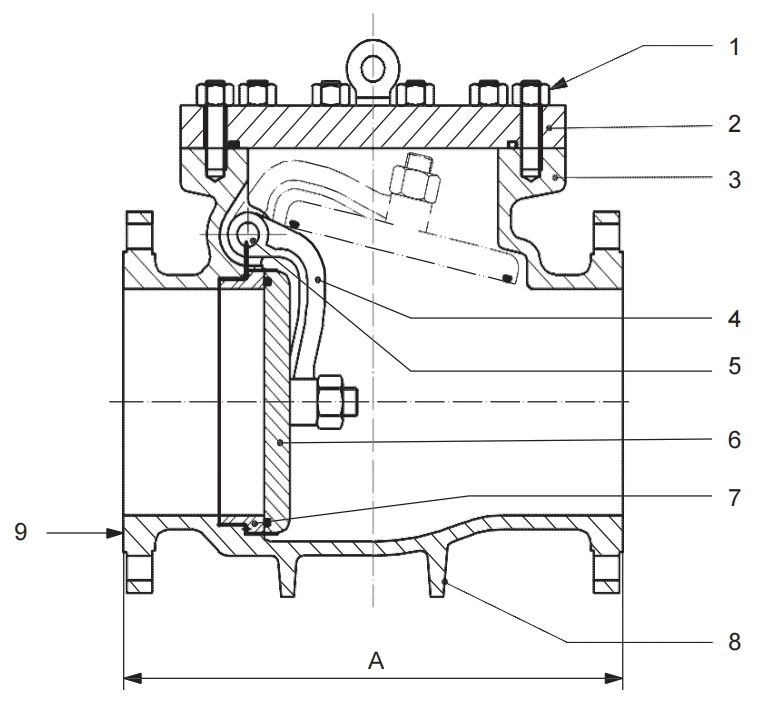

Assembly Drawing

API 6D Swing Check Valve Drawing

Key Part

| Item | Part No. |

| 1 | Cover bolting |

| 2 | Cover |

| 3 | Body |

| 4 | Clapper disc arm |

| 5 | Shaft |

| 6 | Clapper disc |

| 7 | Seat ring |

| 8 | Support legs |

| 9 | Raised face |

Leave Us Your Info

Could you please kindly fulfill the following information when enquiring:

Valve type (ball, gate, globe, check etc.), valve size, pressure class, valve material, and end connection (flanged, butt welding etc.)