API 6D Wafer Check Valve

API 6D Wafer check valves are designed and manufactured in accordance with API 6D, which specifies requirements for pipeline valves. This ensures that the valves meet industry standards for performance, safety, and reliability.

- Valve Type

- Wafer Check Valve

- Standard

- API 6D

- Size

- 2"-48"

- Unit Price

- $40-6800

1. General Configuration

- Type: Wafer check valves are a type of check valve designed to prevent backflow of fluid in a pipeline.

- Connection: Wafer check valves are typically installed between two flanges, hence the name “wafer” due to their thin, disk-like profile.

2. Design and Functionality

- Closure Member: The closure member (or disc) is typically a pivoted plate or clapper that opens and closes in response to fluid flow.

- Sealing: Sealing is achieved by the closure member pressing against a seat when flow is in the desired direction. Backflow causes the closure member to move away from the seat, allowing fluid to pass freely in the reverse direction.

- Spring Assisted: Some wafer check valves may include a spring to assist in closing the valve and preventing unwanted backflow, particularly in applications with low backpressure.

3. Material Construction

- Body: The body of the valve is typically constructed from cast steel, or stainless steel, depending on the application and fluid media.

- Disc and Seat: The closure member (disc) and seat are also made from materials compatible with the fluid media, such as various grades of stainless steel or special alloys for corrosive environments.

4. Installation and Orientation

- Flanged Ends: The wafer design allows the valve to be sandwiched between two pipeline flanges, simplifying installation and maintenance.

- Flow Direction: The valve must be installed in the correct orientation to ensure proper operation. The arrow on the valve body indicates the direction of flow.

5. Application

- Pipeline Systems: Wafer check valves are commonly used in pipeline systems to prevent backflow, especially in pumping stations, compressor stations, and other critical locations where backflow could cause damage or inefficiency.

- Industries: These valves are widely used in the petroleum, natural gas, chemical, and water treatment industries.

6. Compliance and Standards

- API 6D: Wafer check valves are designed and manufactured in accordance with API 6D, which specifies requirements for pipeline valves. This ensures that the valves meet industry standards for performance, safety, and reliability.

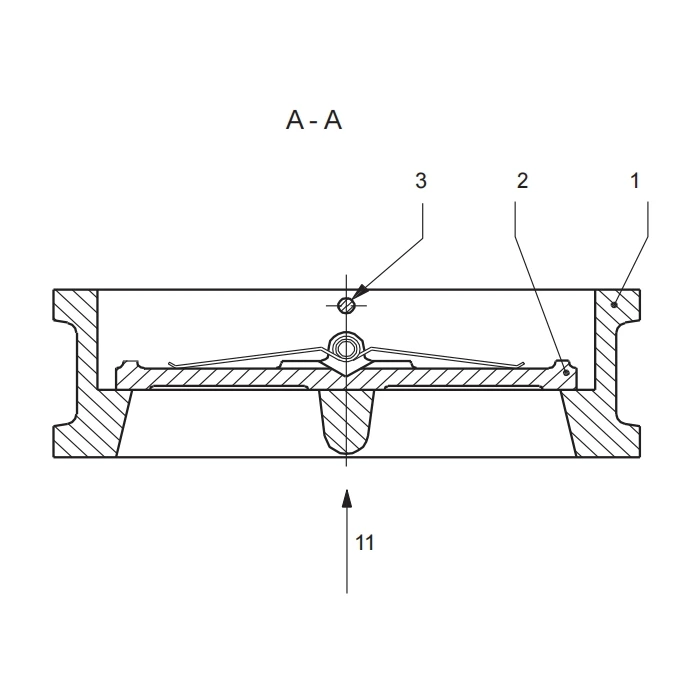

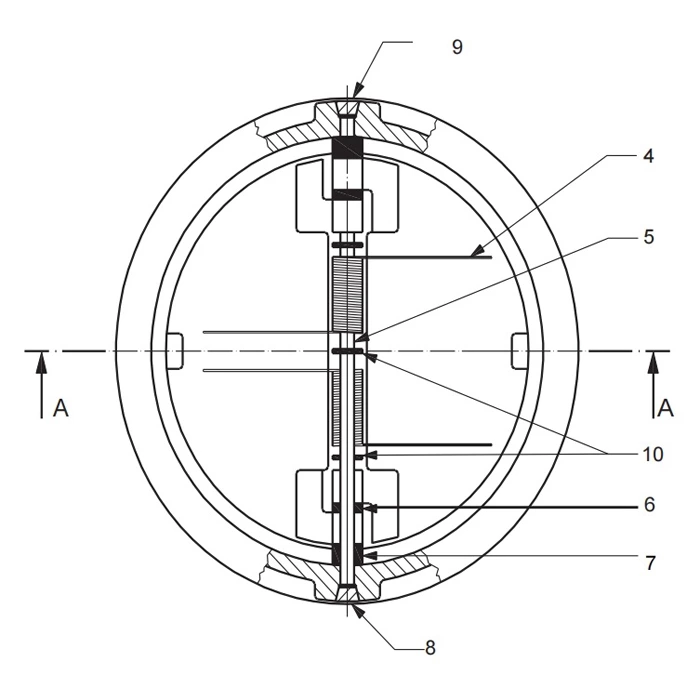

API 6D Wafer Check Valve Drawing

Key Part

| Item | Part Name | Item | Part Name | Item | Part Name | Item | Part Name |

| 1 | body | 4 | spring | 7 | body lug bearings | 10 | spring bearings |

| 2 | closure plate | 5 | hinge pin | 8 | stop pin retainers | 11 | direction of flow |

| 3 | stop pin | 6 | plate lug bearings | 9 | hinge pin retainers |

Leave Us Your Info

Could you please kindly fulfill the following information when enquiring:

Valve type (ball, gate, globe, check etc.), valve size, pressure class, valve material, and end connection (flanged, butt welding etc.)