Tilting Disc Check Valve

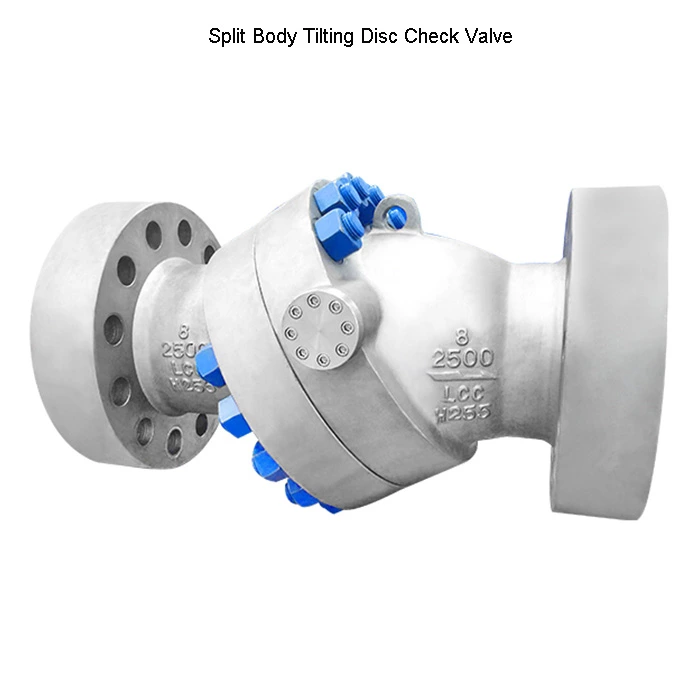

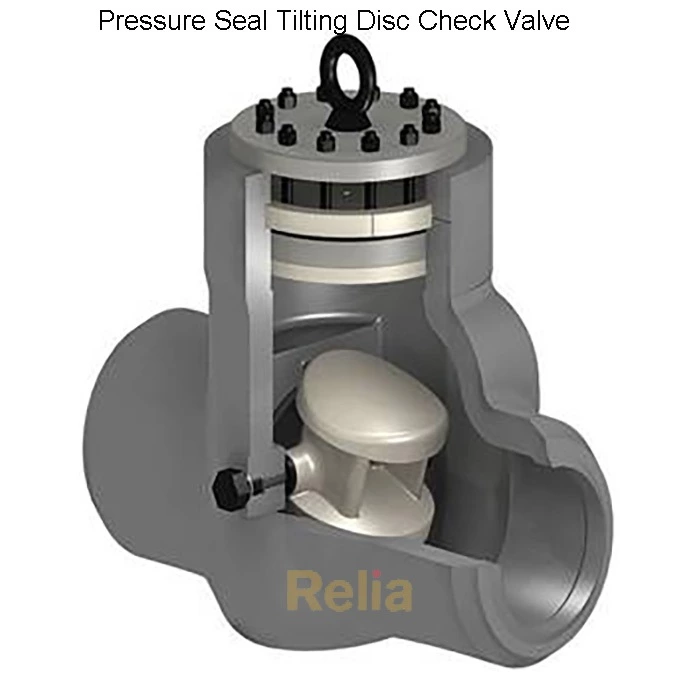

A tilting disc check valve offers a fast-closing solution. Tilting disc check valves provide a Split Body, Pressure Seal or Wafer option with a non-slam design.

Tilting disc check valve is designed for neutral liquids, and are typically installed in pumping applications to prevent backflow in the system. The tilting disc requires only a very low pressure to open.

The characteristic of this valve is "non-slamming". The disc, with its shape, is maintained in the open position by the fluid flow, and its return to the closed position does not cause a sudden violent hit against the seat. Design can be to ASME B16.34 but, also, to EN 12516.

Advantages:

- Stability of low and pulsating flow

- A moderate drop in pressure

- Tight metal seat sealing

- Seat contacts occur only after the disc is seated and closed.

- Quick-closing system

The Tilting Disc Check Valve accomplishes full flow opening by pivoting the disc in the flow media. The opening stroke range is much less than the conventional swing check valves, which reduces opening and closing time. It is critical to controlling flow reversal and reducing water hammer. The tilting disc check valve offers the solution by allowing a fast closing, even with little flow loss.

Tilting disc check valve is designed to open and close faster than standard ones. Rapid operation is required whenever critical components must be protected against backflow immediately. However, many other check valves can only close when the upstream flow is lost completely.

In systems where backflow can occur rapidly, such as pump systems in a high-pressure system, this can lead to major problems. The resulting water hammer can disrupt entire piping and pump systems in extreme cases.

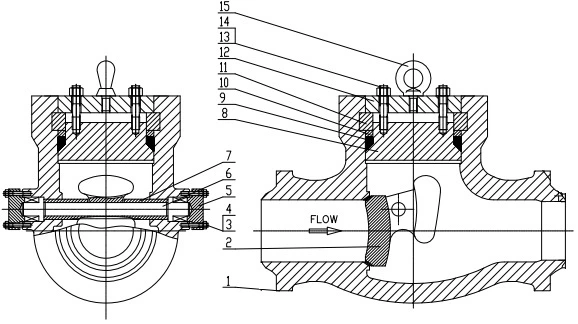

Tilting Disc Check Valve Drawing

Main Part & Typical Material

| No. | Part Name | Material |

| 1 | Body | A216 WCB |

| 2 | Disc | A351 CF8M |

| 3 | Bolt | A193 B7M |

| 4 | Nut | A194 2HM |

| 5 | End Cover | ASTM A105 |

| 6 | Hinge Pin | A182 F6A |

| 7 | Bushing | A182 F6A |

| 8 | Cover | ASTM A105 |

| 9 | Gasket | 316+Graphite |

| 10 | Thrust Ring | ASTM A105 |

| 11 | Separate Ring | ASTM A105 |

| 12 | Cover | ASTM A105 |

| 13 | Cover Bolt | A193 B7M |

| 14 | Cover Nut | A194 2HM |

| 15 | Eye Bolt | Steel |

Application

Because the disc of a tilting disc check valve is mounted at a 15-degree angle, it opens at a medium speed, beginning at 0.6 m/sec with a short response time, which prevents the disc from ‘hammering’ at low speeds and prevents wear on the stem, springs, and bearings. The self-centering seal provides an excellent seal at both high and low-pressure differentials. In addition, the valves can be included with extra springs to increase the response speed if there is a high risk of rapid backflow.

The result is a stable check valve with a fast response time that requires minimal maintenance, which makes this valve suitable for any application requiring a quick response.

How does a tilting disc check valve work?

A tilting disc check valve operates by employing pressure difference. This feature makes the valve operate automatically without a valve actuator, handwheel, or lever. The pressure difference is the principle in which the valve disc opens when the suction pressure is higher than the outlet pressure, and it is high enough to produce energy sufficient to push the disc open. The pump of the piping system provides the fluid pressure. Once the suction fluid pressure opens the valve, it keeps flowing through the valve until the suction pressure drops to be less than the outlet pressure or when there is backflow. In the instance of low suction pressure or backflow, the valve disc automatically reverts to the seating position.

Tilting disc check valve manufacturers also use springs to help the disc return to the seating position immediately after fluid pressure reduces. Such a valve can be installed in either vertical or horizontal positions.

Leave Us Your Info

Could you please kindly fulfill the following information when enquiring:

Valve type (ball, gate, globe, check etc.), valve size, pressure class, valve material, and end connection (flanged, butt welding etc.)