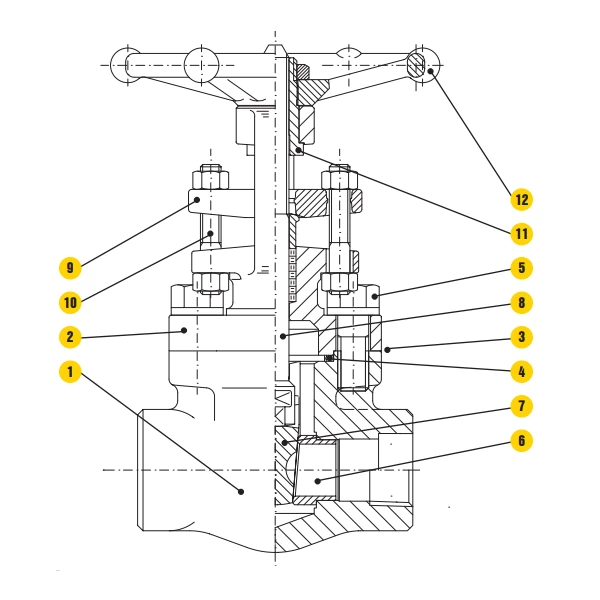

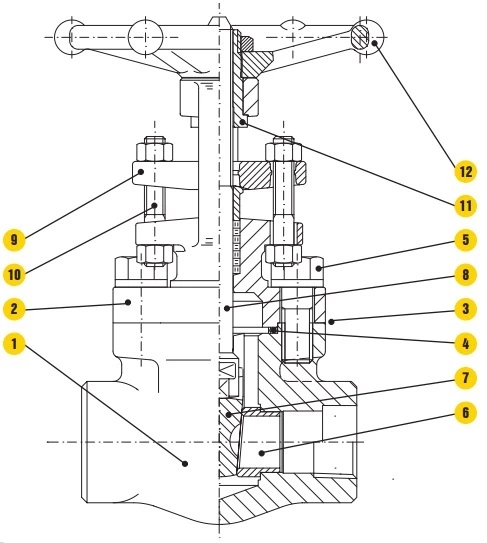

Forged Steel Gate Valve

The forged steel gate valve features an outside screw and yoke (OS&Y), and rising stem. Bolted or welded bonnet joint. Solid wedge gate, integral backseat. full or standard port.

BODY - The body is forged steel and designed to the basic dimensional requirements of the applicable specifications such as API 602 and ASME B16.34. The body is available in both the full or standard port design.

BONNET - The bonnet is forged steel, has an integral backseat, and incorporates the stuffing box.

BONNET JOINT - bolted bonnet or pressure seal and seal welded type.

SEAT RING - The seat rings are pressed into the valve body and wedged into place, forming a seal with the body. The seating surfaces are ground and lapped.

WEDGE - The wedge is a solid wedge design, forged, and the surfaces are ground and lapped.

STEM - The stem is forged steel and it contains an integral back seat shoulder, which mates with the integral back seat of the bonnet. The stem is made to meet the basic size requirements of the relevant standards, like API 602.

Size

1/4" - 2"

Pressure Rating

Class 150 - 2500

End Connections

Flanged, Welded (socket/butt weld), Threaded

Body Material

A105, A105N, LF2, F304, F316, F51, F60, F11, etc.

Standard Specifications

| Design | API 602/ASME B16.34/BS 5352 | Test | API 598 |

| Socket Weld | ASME B16.11 | Screw End | ASME B1.20.1 |

| Butt Weld Ends | ASME B16.25 | End Flanges | ASME B16.5 |

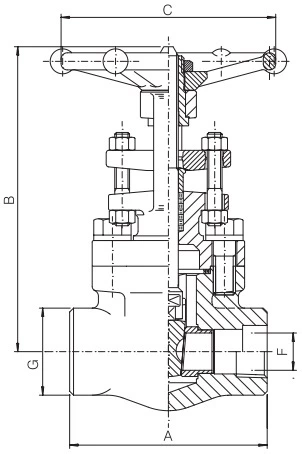

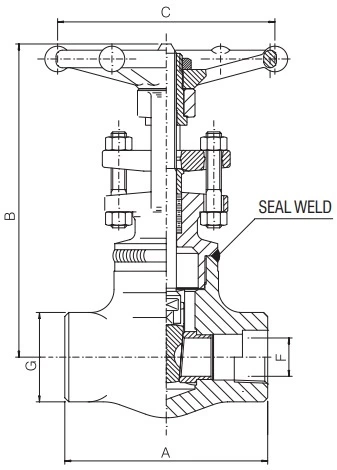

Drawing

Forged steel gate valve drawing

Materil Specifications

| No. | Name | Material |

| 1 | Body | ASTM A105N |

| 2 | Bonnet | ASTM A105N |

| 4 | Gasket | 304+Graphite |

| 5 | Bolting | B7/2H |

| 6 | Seat Ring | 420+STL |

| 7 | Wedge | A276 410 |

| 8 | Stem | A182 F6a |

| 9 | Gland | ASTM A105N |

| 10 | Bolting | A276 410 |

| 11 | Yok Sleeve | A276 420 |

| 12 | Handwheel | Carbon Steel |

Dimensions & Weight

Bolted bonnet forged steel gate valve dimensions

Welded bonnet forged steel gate valve dimensions

Forged Steel Gate Valve, Class 800, Full Port

| Size | 1/4" | 3/8" | 1/2" | 3/4" | 1" | 1-1/4" | 1-1/2" | 2" |

| A | 80 | 80 | 90 | 110 | 127 | 127 | 134 | 152 |

| B | 152 | 152 | 158 | 196 | 225 | 255 | 290 | 358 |

| C | 88 | 88 | 88 | 97 | 138 | 138 | 138 | 172 |

| F | 8 | 9.6 | 14 | 18 | 24 | 30 | 36.5 | 46.5 |

| G | 32 | 32 | 38 | 48 | 56 | 64 | 78 | 85 |

| Weight | 2.1 | 2.1 | 2.3 | 3.7 | 5.9 | 7.4 | 8.3 | 12.5 |

Note: Dimensions in mm, weight in Kg.

Forged Steel Gate Valve, Class 800, Reduced Port

| Size | 1/2" | 3/4" | 1" | 1-1/2" | 2" | 3" |

| A | 80 | 90 | 110 | 127 | 134 | 225 |

| B | 152 | 158 | 196 | 255 | 290 | 313 |

| C | 88 | 88 | 97 | 138 | 138 | 172 |

| F | 9.6 | 14 | 18 | 30 | 36.5 | 50 |

| G | 32 | 38 | 48 | 64 | 78 | 118 |

| Weight | 1.9 | 2.3 | 3.6 | 7.3 | 7.6 | 17.2 |

Note: Dimensions in mm, weight in Kg.

Forged Steel Gate Valve, Class 1500, Full Port

| Size | 1/4" | 3/8" | 1/2" | 3/4" | 1" | 1-1/4" | 1-1/2" | 2" |

| A | 90 | 90 | 110 | 127 | 127 | 127 | 127 | 210 |

| B | 153 | 153 | 190 | 220 | 250 | 282 | 290 | 345 |

| C | 88 | 88 | 97 | 138 | 138 | 138 | 138 | 172 |

| F | 8 | 9.6 | 14 | 18 | 24 | 30 | 36.5 | 48 |

| G | 38 | 38 | 48 | 56 | 64 | 78 | 78 | 85 |

| Weight | 2.4 | 2.4 | 4.1 | 6.2 | 8 | 10.5 | 11 | 20 |

Note: Dimensions in mm, weight in Kg.

Forged Steel Gate Valve, Class 1500, Reduced Port

| Size | 1/2" | 3/4" | 1" | 1-1/2" | 2" |

| A | 90 | 110 | 127 | 127 | 210 |

| B | 152 | 190 | 220 | 282 | 345 |

| C | 88 | 97 | 138 | 138 | 138 |

| F | 9.6 | 14 | 18 | 30 | 36.5 |

| G | 38 | 48 | 56 | 78 | 85 |

| Weight | 2.4 | 3.9 | 6.1 | 10.8 | 20.5 |

Note: Dimensions in mm, weight in Kg.

Other Features

1. GASKET. The bolted bonnet joint design valve uses a contained, controlled compression, spiral wound type gasket.

2. GLAND AND FLANGE. The gland, gland flange assembly utilizes a separate, two piece design. This self aligning design allows the flange to be unevenly tightened while the gland maintains it’s parallel alignment with the stem and stuffing box.

3. GLAND BOLTS AND NUTS. The steel/stainless steel gland bolt and nut assembly is a stud, double nut arrangement. This design allows complete removal from the valve when service is required. The use of industry standard thread full length studs and nuts also allows easy replacement should these items be lost or in need of replacement.

4. YOKE SLEEVE. The yoke sleeve is of forged stainless steel material having a high melting point and is resistant to wear and corrosion.

5. HANDWHEEL. The handwheel is forged carbon steel of an open spoke design. This robust construction along with appropriate sizing allows for ease of operation.

Leave Us Your Info

Could you please kindly fulfill the following information when enquiring:

Valve type (ball, gate, globe, check etc.), valve size, pressure class, valve material, and end connection (flanged, butt welding etc.)