Duplex Ball Valve

Duplex ball valves and super duplex ball valves are extremely corrosion resistant, particularly resistant to not only chloride stress corrosion but also chloride pitting corrosion.

Corrosion Resistance

Ball valve made of duplex stainless steel are extremely corrosion-resistant. They have high resistance to intergranular corrosion. Even in chloride and sulfide environments, duplex stainless steel ball valve exhibits very high resistance to stress corrosion cracking. The super-duplex ball valves are even more resistant to corrosion.

Duplex Steel and Super Duplex Ball Valve Material:

● Duplex 2205(A890 4A, A182 F51,22Cr-5Ni-Mo-N, DIN 1.4462)

● Super Duplex 2507 (A890 5A, A182 F53,25Cr-7Ni-Mo-N,DIN 1.4410)

● Super Duplex (A890 6A, A182 F55,25Cr-7Ni-Mo-N,DIN 1.4501)

● Super Duplex (A182 F60, UNS S32205)

Duplex and Super Duplex Ball Valve Material

| GRADE | FORGING | CASTING | DIN | ||

| ASTM | UNS | ASTM | TYPE | ||

| Duplex 2205 | A182 F51 | S31803 | A890 4A (CD3MN) | 22Cr-5Ni-Mo-N | 1.4462 |

| Supper Duplex 2507 | A182 F53 | S32750 | A890 5A (CE3MN) | 25Cr-7Ni-Mo-N | 1.4410 |

| Supper Duplex | A182 F55 | S32760 | A890 6A(CD3MWCuN) | 25Cr-7Ni-Mo-N | 1.4501 |

| Supper Duplex | A182 F60 | S32205 | |||

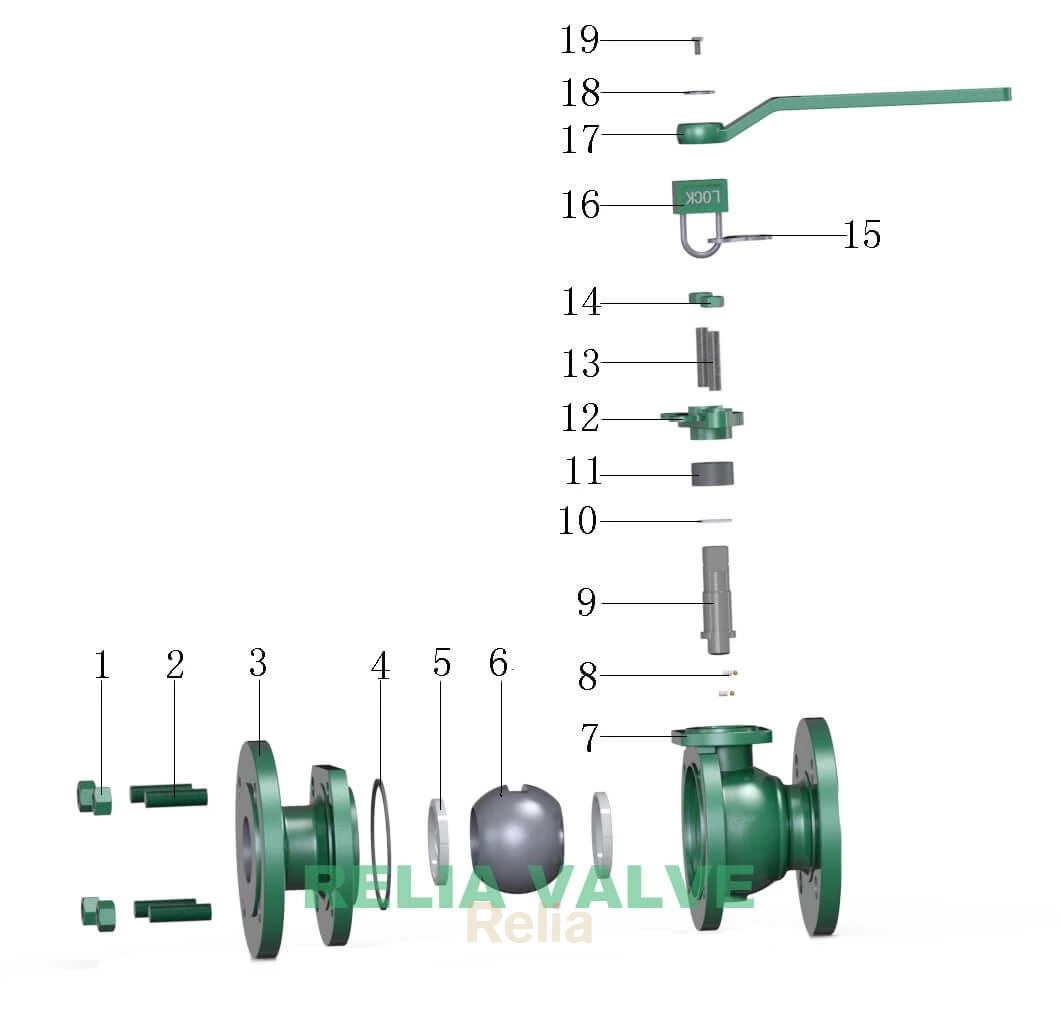

Duplex Steel Ball Valve Drawing

Material Specifications

| No. | Part Name | A890 4A /F51 | A890 5A /F53 | A890 6A/F316 |

| 1 | Nut | ASTM A194 8M | ASTM A194 8M | ASTM A194 8M |

| 2 | Bolt | ASTM A193 B8M | ASTM A193 B8M | ASTM A193 B8M |

| 3 | Bonnet | ASTM A890 4A | ASTM A890 5A | ASTM A890 6A |

| 4 | Gasket | SS316+Graphite | SS316+Graphite | SS316+Graphite |

| 5 | Seat | PTFE,RPTFE | PTFE,RPTFE | PTFE,RPTFE |

| 6 | Ball | A182 F51 | ASTM A182 F53 | ASTM A182 F60 |

| 7 | Body | ASTM A890 4A | ASTM A890 5A | ASTM A351 CF8M |

| 8 | Spring | SS 316 | SS 316 | SS 316 |

| 9 | Stem | A182 F51 | A182 F53 | ASTM A182 F60 |

| 10 | Thrust Washer | PTFE | PTFE | PTFE |

| 11 | Packing | Graphite | Graphite | Graphite |

| 12 | Packing Gland | ASTM A890 4A | ASTM A890 5A | ASTM A890 6A |

| 13 | Bolt | ASTM A193 B8M | ASTM A193 B8M | ASTM A193 B8M |

| 14 | Nut | ASTM A194 8M | ASTM A194 8M | ASTM A194 8M |

| 15 | Hand Stop | Stainless Steel | Stainless Steel | Carbon Steel |

| 16 | Lock | Cast Iron | Cast Iron | Cast Iron |

| 17 | Lever | Carbon Steel | Carbon Steel | Carbon Steel |

| 18 | Gasket | Duplex Steel | Duplex Steel | Duplex Steel |

| 19 | Pin | Stainless Steel | Stainless Steel | Stainless Steel |

Application of duplex ball valves

● Desalination:

- Reverse osmosis (RO)

- Brackish water reverse osmosis (BWRO)

- Seawater reverse osmosis (SWRO)

- Geothermal water

● Offshore oil and gas industry

● Pulp and paper industry

● Chemical industry:

- Sulphuric acid

- Nitric acid

- Saliferous fluids, hydroxide

The microstructures of duplex steel consist of a mixture of austenite and ferrite phases. As a result, duplex stainless steels display properties characteristic of both austenitic and ferritic stainless steels. This combination of properties can mean some

compromise when compared with pure austenitic and pure ferritic grades.

Suitable Temperature

The high chromium content of Duplex stainless steel, which protects against corrosion, causes embrittlement at temperatures over about 300°C. At low temperatures, duplex stainless steels have better ductility than ferritic and martensitic grades. Duplex grades can readily be used down to at least -50 °C.

Leave Us Your Info

Could you please kindly fulfill the following information when enquiring:

Valve type (ball, gate, globe, check etc.), valve size, pressure class, valve material, and end connection (flanged, butt welding etc.)