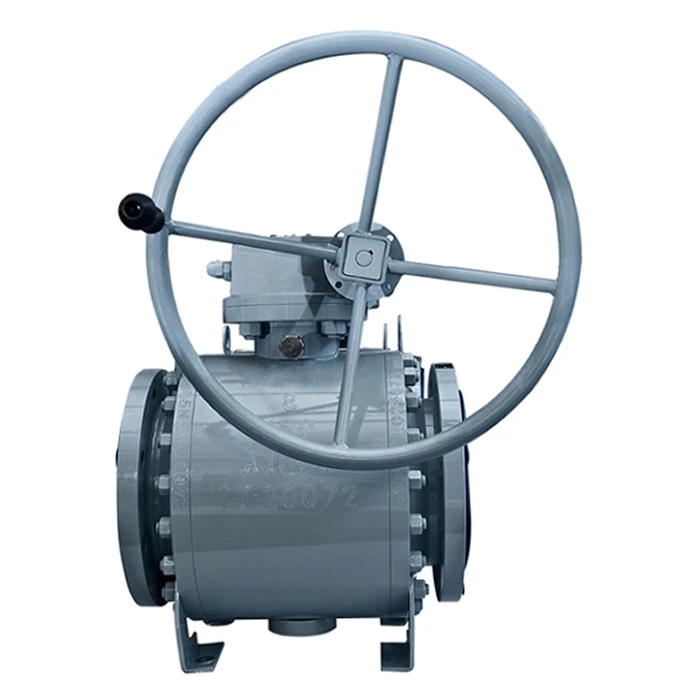

Forged Steel Trunnion Ball Valve

A forged steel trunnion ball valve is a robust ball valve designed for high-pressure and high-temperature applications. Forged steel trunnion ball valve offers enhanced mechanical strength and durability due to its grain structure, making it ideal for critical infrastructure such as oil and gas pipelines, petrochemical plants, and power generation systems

- Valve Type

- Trunnion Mounted Ball Valve

- Size

- 2"-48"

- Pressure Rating

- Class 150-2500

- Body Material

- Forged Steel (A105, LF2, F304, F316, F51 etc.)

- Unit Price

- $80-50000

Design and Mechanism

- Trunnion Support:

In a trunnion ball valve, the ball is fixed by trunnions at the top and bottom, absorbing mechanical stresses and preventing displacement under pressure.

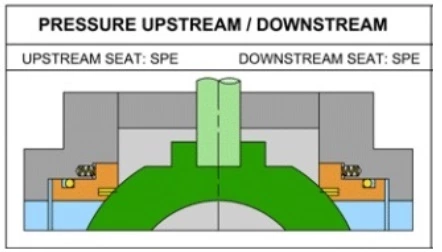

- Sealing System:

In high-pressure conditions, the fluid pressure reinforces the seal by pushing seats against the ball. In low pressure, springs ensure consistent contact between the seat and ball.

- Stem and Actuation:

The stem rotates the ball (90°), with reduced torque due to trunnions bearing axial loads, minimizing wear on the stem and seats.

Key Features and Advantages:

- ·Tight Sealing:

The ball is securely held in place by the trunnions, preventing movement and ensuring a tight seal.

- ·Forged Steel:

Forged steel body and trim allow its application of high pressure, temperature and big sizes.

- Consistent Sealing:

Spring-loaded seats maintain sealing without reliance on system flow pressure, ensuring reliability even at <150 psi

- High-Pressure Applications:

The trunnion design is well-suited for high-pressure environments, as the additional support prevents the ball from being forced out of position.

- Durability:

Trunnion mounted ball valves are designed for demanding industrial environments, capable of handling high-pressure and high-temperature conditions.

- Lower Torque:

The trunnion and stem absorb any additional pressure on the valve, leading to lower operating torque and potentially eliminating the need for a large actuator.

- Double Block and Bleed Function:

Trunnion mounted ball valve features a double block and bleed function, allowing for independent shut-off of the line fluid on both sides of the ball.

Double block

cut the flow from both upstream and downstream

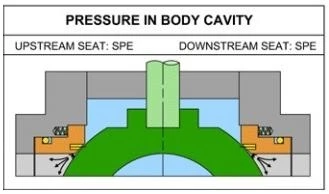

Bleed

automatic cavity pressure relief mechanisms

- Fire-Safe Design:

Trunnion mounted ball valve is designed with fire-safe features, including anti-static systems and anti-blowout stems.

- Cavity Pressure Relief:

To prevent damage to valve seats and ball due to over-pressurisation inside the cavity, trunnion-mounted ball valves are equipped with automatic cavity pressure relief mechanisms.

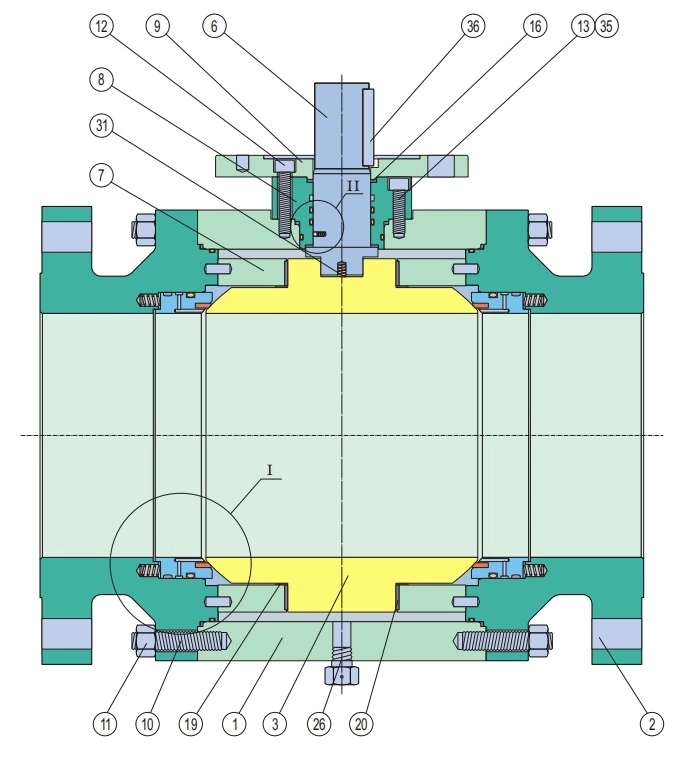

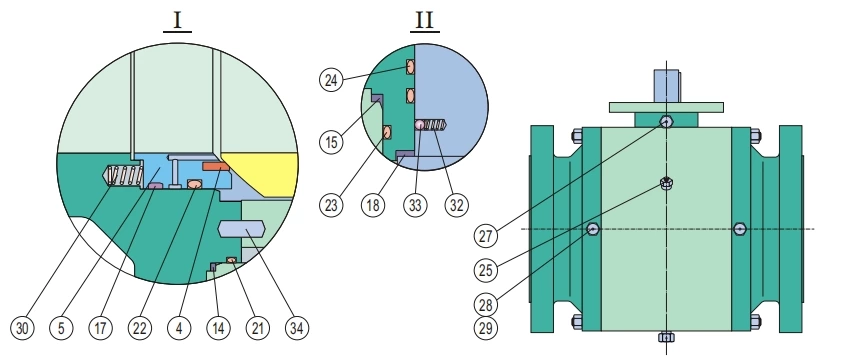

Forged Steel Trunnion Ball Valve Drawing

Material Specifications

| No. | Part | A105/ENP | A105/316 | F316/316 | LF2/316 NACE |

| 1 | Body | ASTMA105N | ASTMA105N | ASTMA182-F316 | ASTMA350-LF2 |

| 2 | Adapter | ASTMA105N | ASTMA105N | ASTMA182-F316 | ASTMA350-LF2 |

| 3 | Ball | ASTMA105N/ENP | ASTMA182-F316 | ASTMA182-F316 | ASTMA182-F316 |

| 4 | Seat Insert | PTFE/Molon/PEEK | PTFE/Molon/PEEK | PTFE/Molon/PEEK | PTFE/Molon/PEEK |

| 5 | Seat Ring | ASTMA105N/ENP | ASTMA182-F316 | ASTMA182-F316 | ASTMA182-F316 |

| 6 | Stem | ASTMA105N/ENP | ASTMA182-F316/17-4PH | ASTMA182-F316/17-4PH | ASTMA182-F316/17-4PH |

| 7 | Trunnion Support | ASTMA105N/ENP | ASTMA105N/ENP | ASTMA182-F316 | ASTMA350-LF2/ENP |

| 8 | Gland Flange | ASTMA105N/ENP | ASTMA105N/ENP | ASTMA182-F316 | ASTMA350-LF2/ENP |

| 9 | Top Flange | ASTMA105N | ASTMA105N | ASTMA182-F316 | ASTMA350-LF2 |

| 10 | Body Stud | ASTMA193-B7 | ASTMA193-B7 | ASTMA193-B8 | ASTMA320-L7M |

| 11 | Body Nut | ASTMA194-2H | ASTMA194-2H | ASTMA194-8 | ASTMA194-7M |

| 12 | Screw | Carbon Steel | Carbon Steel | Stainless Steel | ASTMA320-L7M |

| 13 | Screw | Carbon Steel | Carbon Steel | Stainless Steel | ASTMA320-L7M |

| 14 | *Body Gasket | Graphite | Graphite | Graphite | Graphite |

| 15 | *Gland Gasket | Graphite | Graphite | Graphite | Graphite |

*Recommended Spare Parts

Leave Us Your Info

Could you please kindly fulfill the following information when enquiring:

Valve type (ball, gate, globe, check etc.), valve size, pressure class, valve material, and end connection (flanged, butt welding etc.)